Leave Your Message

In today's rapidly evolving industrial landscape, the demand for efficient heat exchange systems has never been greater. Among the various types of heat exchangers, the Brazed Plate Heat Exchanger stands out for its remarkable efficiency and compact design, making it an ideal choice for a wide array of applications, from HVAC systems to refrigeration. This blog explores the latest innovations and alternative solutions in the field of Brazed Plate Heat Exchanger technology, highlighting the contributions of top manufacturers in China who have established a global footprint with their advanced engineering and quality standards. By examining these innovative designs and their implications for energy efficiency and sustainability, we aim to provide valuable insights into the future of heat exchange solutions that meet the growing demands of various industries worldwide.

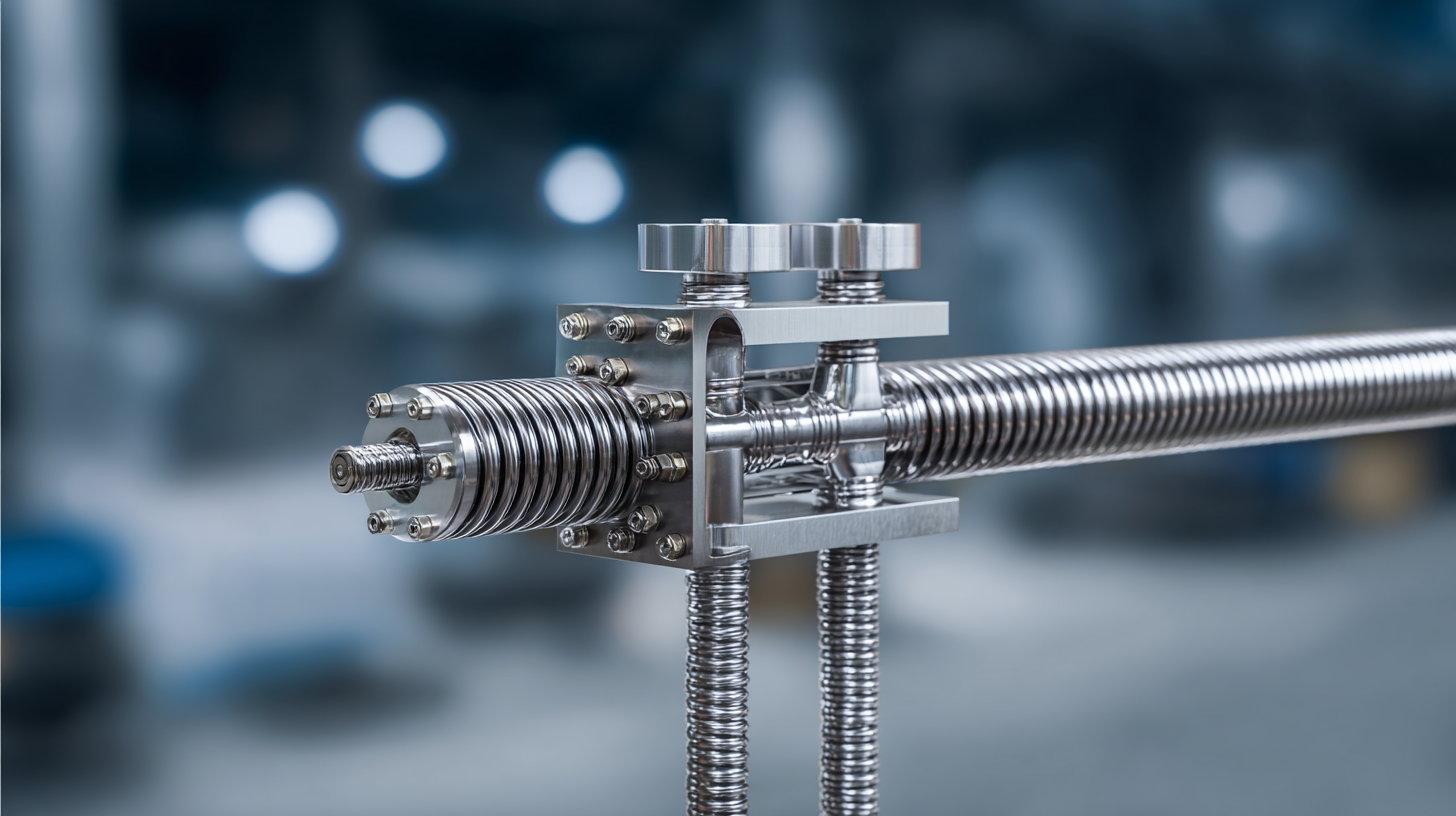

In the realm of brazed plate heat exchanger design, the exploration of innovative materials is essential to enhancing efficiency and performance. As the industry moves towards more sustainable solutions, the incorporation of advanced materials can lead to significant improvements in heat transfer efficiency, durability, and resistance to corrosion. Materials such as high-strength stainless steels and newly developed alloys can provide the required thermal conductivity while minimizing weight and space requirements, allowing for compact designs that fit modern applications.

The burgeoning automotive heat exchanger market, projected to grow at a CAGR of over 6.45% and exceed USD 45.67 billion by 2032, underscores the rising demand for efficient heat exchangers. As vehicle manufacturers seek to improve energy efficiency and reduce emissions, the role of innovative materials becomes even more critical. Moreover, the expected growth in the hydrogen station heat exchanger sector, anticipated to reach USD 4.2 billion by 2034, further highlights the importance of material innovation. As these industries evolve, the development of next-generation heat exchangers that leverage cutting-edge materials will be crucial in meeting the performance demands of the future.

When evaluating the performance metrics of top brazed plate heat exchangers, several key factors come into play, including thermal efficiency, pressure drop, and fouling resistance. These metrics are crucial for industrial applications where heat transfer efficiency can significantly impact operational costs and energy consumption. Advanced brazed plate designs incorporate optimized flow patterns and enhanced surface area, leading to improved heat transfer rates. Additionally, materials used in the brazing process, such as stainless steel, contribute to the overall durability and longevity of the heat exchangers, further enhancing their operational performance.

Another critical performance metric is the ability to handle varying flow rates and temperatures without compromising efficiency. Modern brazed plate heat exchangers are engineered to perform effectively under fluctuating conditions, making them suitable for a range of applications from refrigeration to process heating. Furthermore, their compact design allows for easy installation and integration into existing systems, adding to their appeal in contemporary engineering solutions. By focusing on these performance metrics, industries can choose the right heat exchanger that not only meets their thermal needs but also aligns with sustainability and efficiency goals.

When examining the landscape of brazed plate heat exchangers, conducting a comparative analysis of leading brands and models reveals significant insights into their efficiency and innovation. According to a recent market report by Grand View Research, the global heat exchanger market is expected to reach $24 billion by 2027, with brazed plate heat exchangers comprising a noteworthy segment due to their compact size and high thermal efficiency.

Brands such as Alfa Laval, SWEP, and Danfoss are at the forefront, each offering unique designs and performance metrics that cater to a variety of industrial applications.

Brands such as Alfa Laval, SWEP, and Danfoss are at the forefront, each offering unique designs and performance metrics that cater to a variety of industrial applications.

Alfa Laval's innovative designs, for instance, showcase models with a thermal efficiency exceeding 95%, which is a benchmark for modern heat exchange solutions. In contrast, SWEP has developed a line known for its superior corrosion resistance and longevity, making it a preferred choice for aggressive fluid handling. Moreover, Danfoss emphasizes energy savings, boasting that their latest models can reduce energy consumption by up to 30% when compared to conventional heat exchangers. By analyzing these standout features and performance statistics, stakeholders can make informed decisions tailored to their specific operational needs and environmental goals.

As industries continue to evolve, brazed plate heat exchangers (BPHEs) are witnessing significant innovations driven by the need for efficiency and sustainability. One of the prominent trends in BPHE technology is the development of new materials that enhance thermal conductivity while also reducing corrosion. Manufacturers are increasingly exploring advanced alloys and coatings that not only improve performance but also extend the lifespan of these exchangers in demanding environments. This shift towards more durable materials reflects a broader commitment to sustainability, as longer-lasting products contribute to reduced waste and lower maintenance costs.

Moreover, the integration of smart technologies into BPHEs is reshaping their functionality. IoT-enabled devices are being incorporated to monitor performance in real-time, allowing for precise adjustments and predictive maintenance. This trend minimizes downtime and maximizes operational efficiency, catering to industries that require reliable heat exchange solutions. As energy efficiency regulations tighten, the focus on automated control systems in BPHE design signifies a future where adaptability and intelligence are key components of engineering excellence. Overall, these advancements mark a pivotal moment in the evolution of brazed plate heat exchangers, aligning with future trends that prioritize performance, longevity, and smart technology integration.

In the evolving landscape of heat exchanger manufacturing and usage, sustainable practices are increasingly recognized as vital for reducing environmental impact. One promising area is waste heat recovery, which has the potential to transform industrial emissions into profitable energy sources. Despite its advantages, this opportunity remains largely untapped. By integrating effective heat exchange systems, industries can significantly enhance their energy efficiency, thereby supporting sustainability goals while simultaneously improving their bottom line.

Furthermore, innovative techniques for harnessing cold energy are gaining traction, contributing to the sustainable ethos within the sector. These technologies offer pathways to convert cold energy into power, showcasing how heat exchangers can play a transformative role not only in waste heat recovery but also in broader energy management strategies. As industries seek to mitigate their carbon footprint, embracing these advancements in heat exchanger technology will be crucial for creating a more sustainable future in manufacturing practices.

This chart illustrates key metrics related to sustainable practices in the manufacturing of brazed plate heat exchangers. The focus is on energy efficiency, material recyclability, lifecycle emissions, and the amount of manufacturing waste, providing insights into the effectiveness of innovative solutions in the field.