Leave Your Message

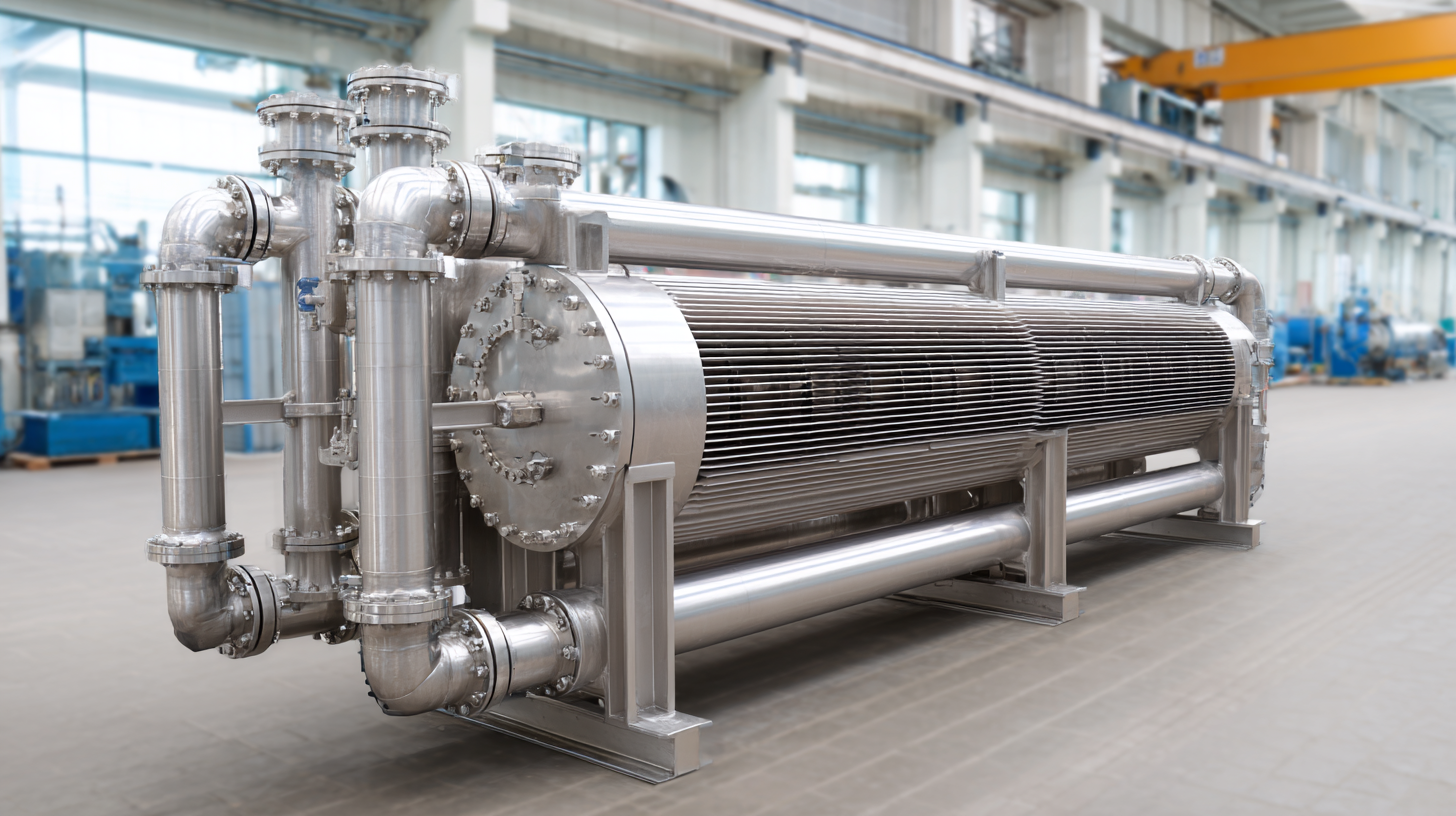

In an era where energy efficiency and sustainable practices are paramount, the Plate To Plate Heat Exchanger emerges as a key player across various industries. According to a recent report by the Global Heat Exchanger Market, the demand for heat exchangers is projected to reach $19.4 billion by 2027, highlighting the crucial role they play in optimizing thermal processes. Furthermore, the adoption of advanced materials and technological innovations has significantly enhanced the performance and reliability of these systems. As industries strive for quality upgrades and cost efficiency, the Plate To Plate Heat Exchanger stands out due to its superior heat transfer capabilities, compact design, and reduced energy consumption. With China leading the manufacturing of these critical components, the global trend towards "China manufacturing, quality upgrade, and worldwide sales" underscores the importance of selecting the right heat exchanger for optimal performance in specific industrial applications.

When choosing the ideal plate to plate heat exchanger for your industry, several critical factors must be considered. Firstly, thermal performance is paramount. According to a comprehensive review on thermal performance enhancement of plate heat exchangers, advancements in materials and design can significantly improve heat transfer efficiency. Industries must assess the specific thermal requirements of their applications to select a heat exchanger that meets or exceeds these needs.

Another crucial aspect is the potential for fouling, which can drastically reduce efficiency and increase maintenance costs. A review discussing fouling mitigation effects highlights that understanding the specific fluids being processed—as well as their temperatures and pressures—can help in selecting a heat exchanger designed to minimize fouling. Furthermore, with the gasketed plate heat exchanger market projected to grow to USD 2.27 billion by 2034, it is evident that industries are increasingly recognizing the value of these systems for both energy recovery and water treatment applications. Selecting the right heat exchanger involves balancing these technical specifications and market trends to optimize performance and sustainability.

| Factor | Description | Importance Level |

|---|---|---|

| Material Compatibility | The heat exchanger materials should be compatible with the liquids being processed to prevent corrosion and contamination. | High |

| Temperature Range | Consider the operating temperature range to ensure the heat exchanger can efficiently handle the required thermal loads. | High |

| Pressure Limits | Check the maximum pressure rating of the heat exchanger to avoid failures during operation. | Medium |

| Maintenance Needs | Evaluate the ease of maintenance to ensure timely servicing and prolonged lifespan. | Medium |

| Energy Efficiency | Consider the energy consumption and efficiency of the heat exchanger to optimize operational costs. | Very High |

| Size and Footprint | Evaluate the space available for installation and select a model that fits without compromising on performance. | Medium |

| Cost | Consider upfront costs versus long-term savings to choose a cost-effective option. | High |

When selecting the ideal plate-to-plate heat exchanger for an industry, understanding thermal efficiency is crucial. Research indicates that the incorporation of nanofluids can significantly enhance heat transfer performance in these devices. For instance, studies have shown that adding silicon carbide (SiC) nanofluids can optimize the thermal performance of plate heat exchangers at optimal concentrations, with 0.60% being the most effective for improving heat transfer rates. The unique properties of these nanofluids allow for better thermal conductivity compared to conventional fluids, making them an attractive option in applications demanding high efficiency.

Additionally, geometrical factors such as plate spacing and inclination angle play a pivotal role in the thermal performance of plate heat exchangers. Recent investigations highlight the effectiveness of V-shaped double-winglet ribs inside plates, which act as turbulators. These designs can significantly augment the heat transfer rate by creating complex flow patterns, contributing to improved energy efficiency. Moreover, optimizing the channel dimensions of pillow plate heat exchangers has shown to enhance heat exchange rates, making them suitable for various industrial applications. Such advancements demonstrate the continuous evolution and importance of thermal efficiency ratings in determining the best heat exchanger for specific operational needs.

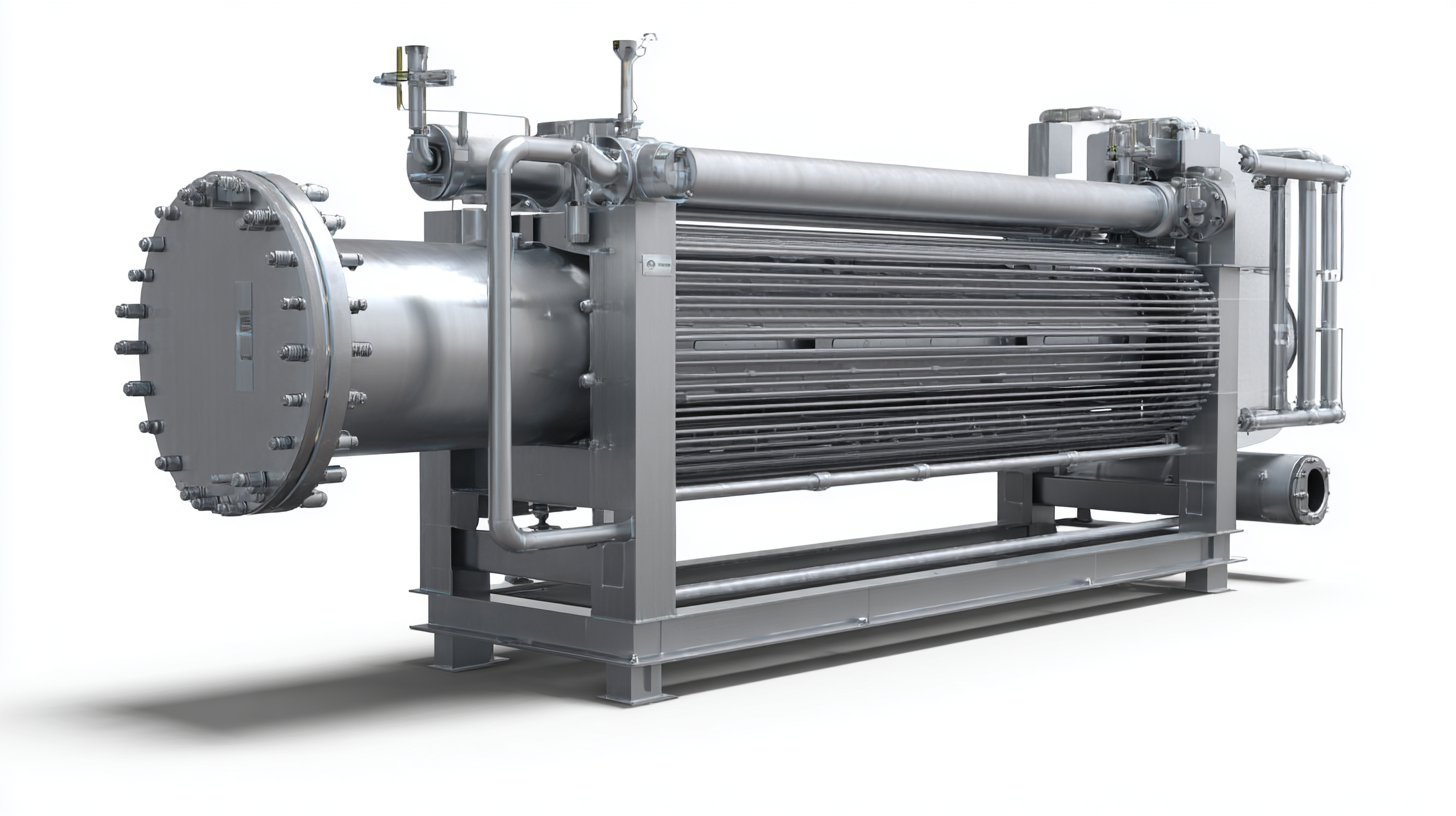

When selecting a plate-to-plate heat exchanger for your industry, material selection plays a crucial role in determining both performance and durability. The right materials not only enhance the efficiency of heat transfer but also ensure the longevity of the equipment. Common materials like stainless steel and titanium are favored for their corrosion resistance and ability to withstand high temperatures. For industries such as chemical processing or food and beverage, where cleanliness and hygiene are paramount, the choice of material can directly influence compliance with health regulations.

Additionally, the thermal conductivity of the materials used significantly impacts the heat exchanger's effectiveness. Copper, for instance, boasts excellent thermal conductivity, making it suitable for applications requiring rapid heat exchange. However, the balance between thermal performance and mechanical strength should be carefully considered. Factors such as fluid compatibility and environmental conditions must also be taken into account, as they can affect the performance over time. Ultimately, understanding the implications of material selection will enable industries to optimize their heat exchanger systems for enhanced durability and efficiency.

When selecting a plate to plate heat exchanger, maintenance requirements play a crucial role in ensuring its longevity and efficiency. A well-maintained heat exchanger operates with optimal thermal performance, which can significantly reduce energy costs and enhance overall production efficiency. Key maintenance practices include regular inspections to identify wear and tear, cleaning the plates to prevent fouling, and monitoring the pressure drop across the unit. By proactively addressing these factors, industries can avoid costly downtimes and extend the service life of their heat exchangers.

Moreover, choosing a heat exchanger with easy disassembly and cleaning features can streamline maintenance tasks. Designs that allow for quick access to plates can facilitate more effective cleaning and inspections, minimizing downtime significantly. Additionally, considering materials that withstand the specific operating conditions—such as temperature and corrosive substances—is vital for long-term reliability. Ultimately, a commitment to proper maintenance not only enhances the efficiency of plate to plate heat exchangers but also ensures they continue to meet the rigorous demands of the industry.

Choosing the right plate-to-plate heat exchanger is crucial for maintaining regulatory compliance in various industries. With the increasing emphasis on safety and environmental standards, heat exchangers must adhere to stringent guidelines set forth by organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). According to a recent report by Research and Markets, the global heat exchanger market is expected to reach $19.2 billion by 2025, driven by the demand for energy-efficient and compliant solutions across sectors like food processing, pharmaceuticals, and HVAC.

When selecting a heat exchanger, it's essential to evaluate its compliance with industry-specific standards. For instance, food and beverage industries require equipment that meets sanitation guidelines established by the Food and Drug Administration (FDA). This means choosing a heat exchanger made of non-corrosive materials and designed for easy cleaning.

**Tips:** Always request documentation that demonstrates compliance with relevant regulations before making a purchase. Additionally, consider heat exchangers with certifications such as ASME or EHEDG (European Hygienic Engineering and Design Group) to ensure you meet the necessary safety and health standards. Regularly review and update your compliance knowledge to keep pace with changing regulations and technology advancements in the industry.