Leave Your Message

Choosing the right Heating Plate Heat Exchanger is crucial for achieving optimal efficiency in various industrial applications. With a wide array of options available in the market, understanding the specific requirements of your operation is vital. This decision not only impacts the overall performance of the heating system but also influences energy consumption, maintenance costs, and the longevity of the equipment.

In this guide, we will explore the essential factors to consider when selecting a Heating Plate Heat Exchanger, including material compatibility, thermal performance, and flow rates. By focusing on these key aspects, industries can enhance heat transfer efficiency and reduce operational downtime.

Whether you are in the food processing, chemical, or HVAC sectors, making an informed choice can lead to significant energy savings and improved product quality. Let’s dive into the critical elements that will help you choose the best Heating Plate Heat Exchanger for your needs.

When selecting a heating plate heat exchanger for industrial applications, several key factors must be taken into account to ensure optimal efficiency. First and foremost, the material compatibility is crucial. The choice of materials should align with the specific fluids being processed, considering factors like corrosion resistance and thermal conductivity. Commonly used materials include stainless steel and titanium, which can withstand varying temperatures and pressures while preventing contamination.

Another significant aspect is the heat transfer area, which directly influences the exchanger's performance. A larger surface area facilitates better heat exchange, enhancing overall efficiency. Additionally, the design configuration should match the application requirements; for example, counterflow designs typically offer higher thermal efficiency than parallel-flow designs. Moreover, it’s essential to consider the maintenance needs, ensuring that the selected model allows for easy cleaning and inspection to maintain consistent performance over time. By meticulously evaluating these factors, industries can select the most effective heating plate heat exchanger tailored to their specific applications.

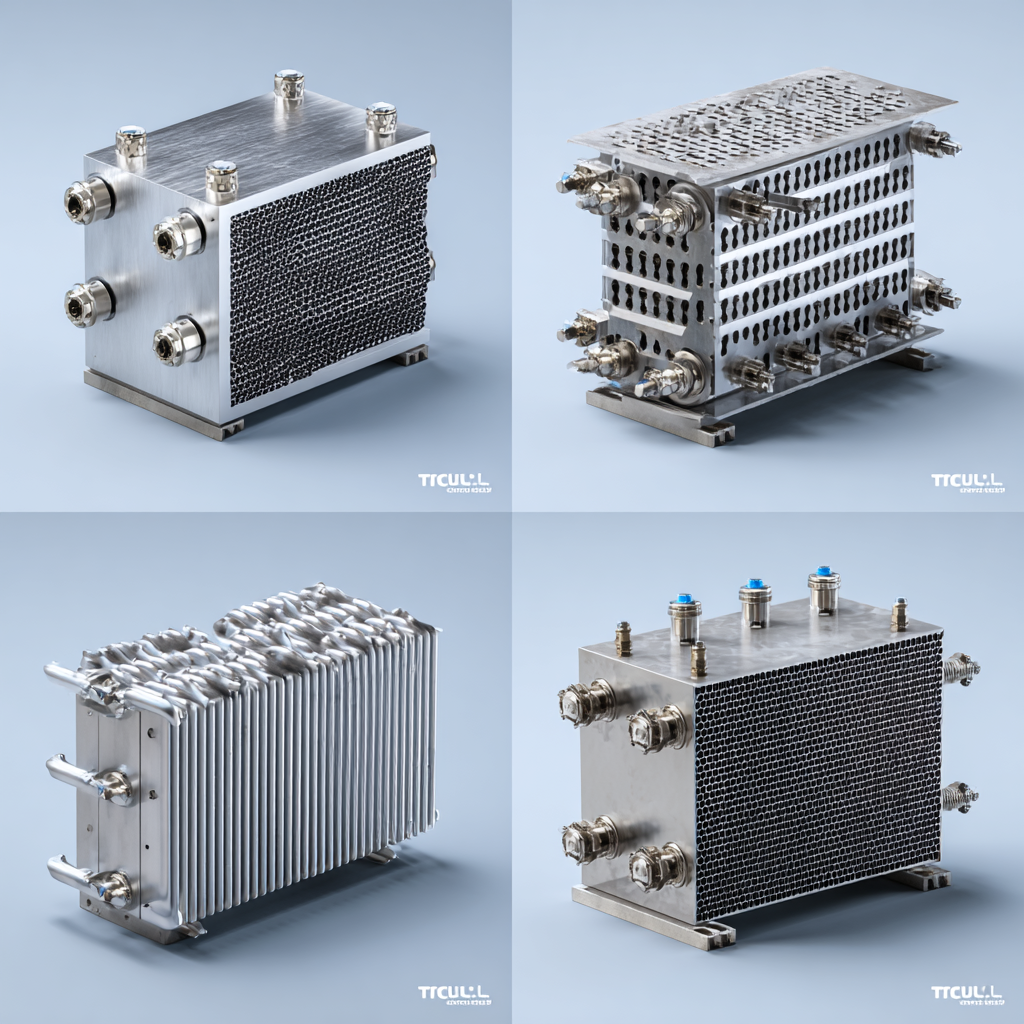

When selecting a heating plate heat exchanger for industrial applications, it's essential to understand the different types available. The most common types include conventional plate heat exchangers, which feature a series of metal plates stacked together, and welded plate heat exchangers, which offer a more compact and robust design. Additionally, semi-welded heat exchangers combine aspects of both systems, providing flexibility for various heating needs. Each type presents unique advantages, depending on factors such as space constraints, operating temperatures, and the nature of the fluids involved.

Tips: Consider the thermal requirements of your process. If you work with high-viscosity fluids, a semi-welded design may improve efficiency by minimizing the risk of blockage. Also, ensure that the selected heat exchanger has a high thermal conductivity to optimize heat transfer, which is crucial for energy savings in the long run.

You should also evaluate maintenance and cleaning needs. Plate heat exchangers tend to be easier to maintain due to their modular design, allowing for individual plate replacements. Regular inspections can help in maintaining optimal efficiency, preventing downtime and extending the lifespan of your equipment. By carefully assessing these factors, you can make an informed decision that enhances your industrial processes.

When selecting a heating plate heat exchanger for industrial applications,

evaluating material compatibility is crucial for achieving optimal efficiency and durability. Different materials such as

stainless steel, titanium, and various polymers offer distinct thermal conductivity and corrosion resistance properties, which directly impact the heat exchanger's performance.

For instance, stainless steel is often favored in food processing and pharmaceutical industries due to its resistance to corrosion and ease of cleaning, while

titanium may be preferred in marine or chemical environments where aggressive media are present.

The choice of material should not only consider the fluid type being processed but also the operating temperature and pressure conditions.

Compatibility with the working fluids is essential to prevent corrosion, fouling, and other forms of degradation that could reduce the heat exchanger's lifespan and efficiency.

It is also important to account for thermal expansion differences between materials, which can lead to stress and potential failure if not properly managed.

Thus, a thorough evaluation of material properties against the specific application requirements is key to optimizing the performance and longevity of heat exchangers in demanding industrial settings.

In the industrial realm, optimizing heat exchange efficiency is paramount, particularly when analyzing various heat transfer efficiency ratings. Recent studies highlight the significant impact that innovative designs and materials have on enhancing thermal performance. For instance, the integration of advanced nanofluids has demonstrated improved heat transfer capabilities in contexts such as hydrogen liquefaction, reflecting a broader trend in harnessing nanocomposites for enhanced thermal management in industrial applications.

Furthermore, the exploration of unorthodox designs, such as twisted tape inserts in heat exchangers, showcases passive methods to boost heat transfer under turbulent conditions. These innovations emphasize the importance of comprehensive performance assessments in the design phase, aiding industries in choosing the most efficient heating plate heat exchangers tailored to their specific operational demands. As the demand for high-density electronic cooling solutions escalates, understanding these thermal dynamics becomes critical for achieving optimal efficiency in various industrial settings.

When selecting a heating plate heat exchanger for industrial applications, maintenance and cleaning considerations are pivotal for ensuring long-term reliability and optimal efficiency. According to a report by the Heat Exchange Institute, routine maintenance can enhance the operational lifespan of heat exchangers by up to 30%. This underscores the need for a comprehensive maintenance strategy that includes regular inspections and timely cleaning to prevent fouling and scaling, which are common issues that can severely diminish heat transfer efficiency.

Cleaning protocols should be tailored to the specific type of fouling encountered in the heat exchanger. A study published in the Journal of Industrial Heat Transfer indicates that implementing a combination of chemical cleaning and mechanical cleaning techniques can restore heat exchanger efficiency by as much as 50%. Moreover, manufacturers recommend a cleaning interval based on the operating environment, suggesting every 3-6 months for high-fouling processes, ensuring that equipment operates within peak thermal efficiency ranges. Regular cleaning not only prolongs the operational reliability of heat exchangers but also significantly reduces energy costs associated with increased heat transfer rates.

This chart displays the efficiency levels of different heating plate heat exchangers based on various maintenance practices. Regular maintenance enhances their performance and reliability in industrial applications.