Leave Your Message

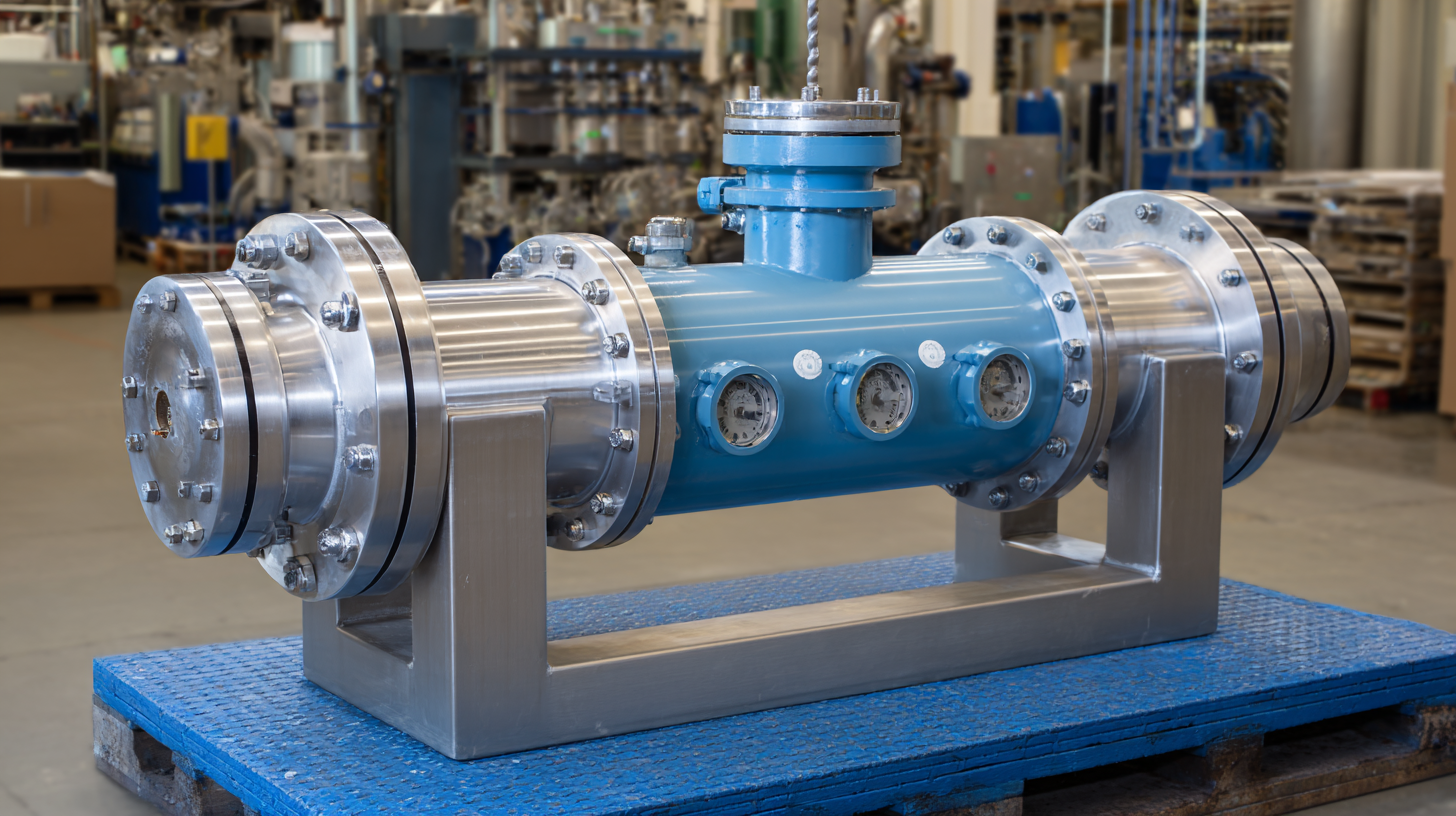

Heat Exchanger Maintenance is a critical aspect in ensuring the efficiency and longevity of heat exchangers, which are integral to various industrial processes. According to a report by the International Energy Agency, heat exchangers account for nearly 20% of the total energy consumption in industrial applications. With their significant role in energy transfer, preventative maintenance strategies can lead to substantial cost savings, extend equipment life, and enhance performance. A well-maintained heat exchanger not only improves system efficiency but also minimizes the risk of unexpected downtime, which can be detrimental to production schedules.

In this blog, we will explore the top strategies for effective heat exchanger maintenance techniques, highlighting best practices, common pitfalls, and the importance of regular inspections and cleaning to achieve optimal operation.

When it comes to maintaining heat exchangers, scheduled inspections are crucial for ensuring their efficiency and longevity. Regularly checking these systems not only prevents unexpected breakdowns but also aligns with sustainable practices that minimize environmental impact. As seen in various sectors, adherence to regulatory standards is essential, mirroring the commitment to eco-friendly operations as highlighted in recent environmental reports.

**Tip:** Develop a structured inspection schedule that includes visual checks for signs of wear, leaks, or corrosion. These routine assessments can help catch potential issues before they escalate, ensuring optimal performance.

Another best practice is to document all maintenance activities meticulously. Keeping detailed records not only assists in compliance with environmental regulations but also provides insight into the operational history of the heat exchanger, allowing for better decision-making in future maintenance tasks.

**Tip:** Implement a maintenance checklist that includes filter replacements, pressure tests, and cleaning procedures. This proactive approach not only enhances the reliability of the system but also contributes to a more sustainable operation overall.

Effective maintenance of heat exchangers is critical for ensuring operational efficiency and longevity. The planned growth of the global industrial heat exchanger market, projected to reach $18.2 billion by 2023, highlights the increasing reliance on these systems across various sectors. With an estimated compound annual growth rate (CAGR) of 6.5% from 2024 to 2032, industries are becoming more aware of the need for implementing robust cleaning and maintenance strategies. Regular cleaning not only enhances heat transfer efficiency but also prevents costly downtimes due to equipment failures.

In a similar vein, the North American plate heat exchanger market showcases a significant forecasted growth, exceeding $808.3 million as of 2023, with an impressive CAGR of over 8.1% through 2032. This growth can be attributed to the rising energy demands and stringent emission regulations, necessitating more effective maintenance practices. By focusing on key cleaning techniques and routine inspections, industries can capitalize on technological advancements, improve energy efficiency, and ensure compliance with environmental standards, reinforcing the importance of proactive maintenance strategies within the heat exchanger landscape.

Monitoring temperature and pressure is crucial for maintaining the optimal performance of heat exchangers. According to a report by the American Society of Mechanical Engineers (ASME), approximately 35% of heat exchanger failures can be attributed to improper monitoring and control of these parameters. Regularly monitoring these metrics not only helps in avoiding costly downtime but also extends the lifespan of the equipment. Temperature fluctuations can suggest fouling or scaling, while pressure drops can indicate leaks or blockages. Both can lead to reduced efficiency and increased operational costs.

**Tip:** Implement a digital monitoring system for real-time analysis. Digital sensors can provide accurate temperature and pressure readings, which can be logged and analyzed over time to identify trends and preemptively address issues.

Moreover, standard maintenance practices should include routine checks of these parameters. According to a study by the National Association of Corrosion Engineers (NACE), facilities that adopted a proactive maintenance strategy saw a 20% increase in their heat exchanger efficiency. By scheduling periodic inspections and using predictive maintenance strategies, operators can anticipate failures before they occur, ultimately saving time and resources.

**Tip:** Train maintenance personnel to recognize the signs of abnormal temperature and pressure readings. Early detection through proper training can significantly reduce the risk of catastrophic failures and enhance overall system reliability.

Heat exchangers are vital components in many industrial processes, but they can encounter a range of issues that affect their performance.

Common problems include fouling, leaks, and thermal performance degradation.

Troubleshooting these issues promptly can prevent costly downtime and prolong the life of the equipment.

One effective strategy for addressing fouling is regular cleaning and inspection.

Using chemical cleaning agents can help remove buildup without damaging the exchanger surfaces.

Additionally, implementing a routine maintenance schedule to monitor pressure drops can provide early signs of fouling before it becomes a significant problem.

For leaks, it is important to identify the source quickly. A thorough visual inspection combined with pressure testing can reveal weak points.

Applying sealing compounds or replacing gaskets may provide a quick fix, while more extensive repairs might require professional services.

Regularly checking the condition of seals and connections is essential to avoiding leaks altogether.

When it comes to heat exchanger maintenance, adhering to health and safety guidelines is paramount. These guidelines ensure that technicians not only protect themselves but also maintain the integrity of the equipment. Regular inspections and maintenance tasks can pose risks, including exposure to hazardous materials or high pressures. It’s crucial for maintenance teams to be trained in recognizing these dangers and following proper procedures to mitigate risks.

Tip: Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and hard hats when performing maintenance on heat exchangers. This not only safeguards individual workers but also promotes a culture of safety in the workplace.

Moreover, clear communication of safety protocols is essential during maintenance operations. Ensuring that all team members are aware of potential hazards and the correct response strategies can significantly reduce accidents. Leveraging technology, such as scheduling maintenance via software that includes safety checklists, can enhance compliance with health and safety standards.

Tip: Conduct regular safety drills and training sessions to reinforce the importance of following safety guidelines, ultimately fostering a proactive safety culture among the team.