Leave Your Message

As we look towards 2025, the landscape of Heating Plate Heat Exchanger technology is rapidly evolving, reflecting both advancements in engineering and shifting global market demands. According to a recent report by ResearchAndMarkets, the heat exchanger market is projected to reach $19.91 billion by 2025, with the demand for heating plate models increasing significantly due to their compact design, high efficiency, and versatility across various industries. Moreover, the growing emphasis on energy efficiency and sustainability is pushing manufacturers to innovate and optimize these systems further.

Global buyers need to stay informed about these emerging trends including improved heat transfer capabilities, advanced materials, and IoT integration in heating plate heat exchangers, which will not only enhance performance but also drive competitive advantage in an increasingly eco-conscious market.

Recent advancements in heating plate heat exchanger design have been pivotal in enhancing thermal efficiency and operational performance. According to the latest report from ResearchAndMarkets, the global heat exchanger market is projected to grow at a CAGR of 8.6% from 2021 to 2026, driven significantly by the demand for compact and efficient heat transfer solutions.

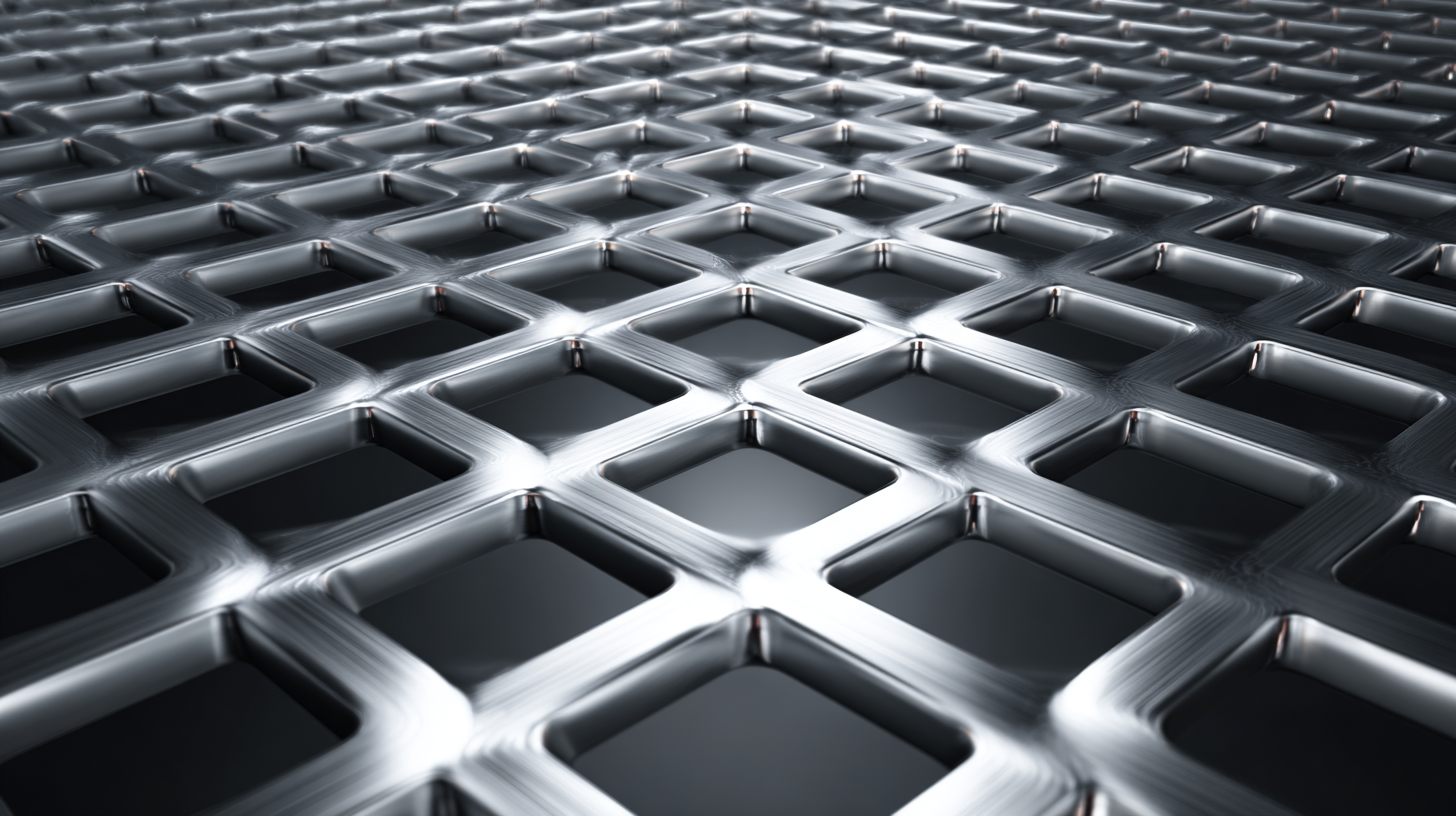

Innovations such as the integration of advanced materials, including lightweight alloys and composite materials, have facilitated better heat conductivity and durability, allowing manufacturers to produce units that are not only lighter but also resistant to corrosion and thermal fatigue.

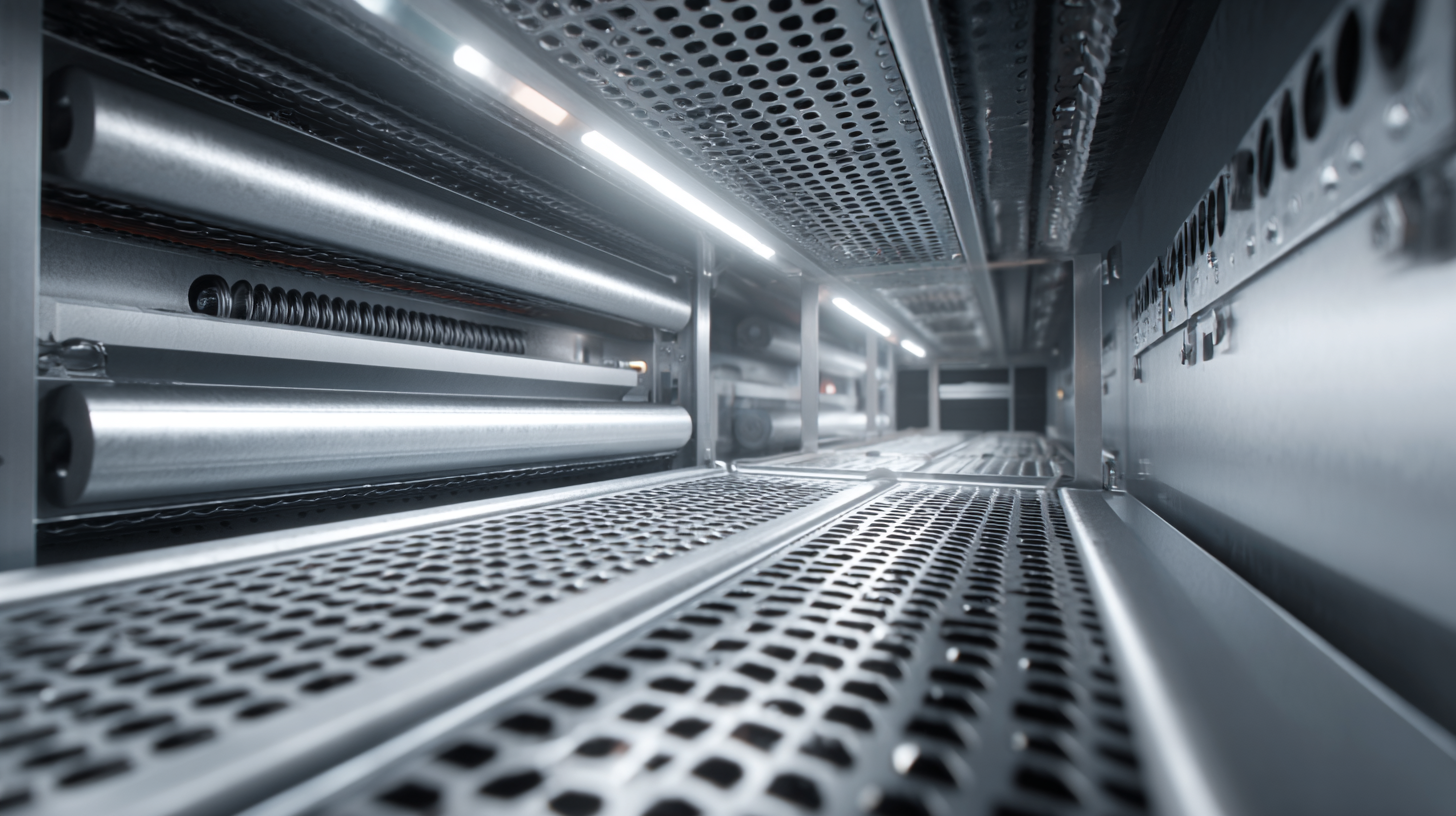

Moreover, the introduction of computer simulations and sophisticated modeling techniques have transformed the design phase, enabling engineers to optimize flow patterns and minimize pressure drops. A study published by the ASHRAE Journal highlighted that these modern designs can improve heat transfer rates by as much as 30% compared to traditional models.

Furthermore, enhanced manufacturing processes, such as laser welding, have improved the reliability and efficiency of heating plate heat exchangers, allowing for higher operational pressures and temperatures. As these innovations continue to evolve, global buyers should stay informed about the latest trends to remain competitive in their respective industries.

As we look towards 2025, several key factors are driving the global demand for heating plate heat exchangers. The market is projected to see significant growth, with the gasketed plate heat exchanger segment alone expected to reach $2.27 billion by 2034, showcasing a compound annual growth rate (CAGR) of 3.67%. This expansion is largely fueled by advancements in energy-efficient technologies and the increasing focus on sustainability across various industries. Companies are investing in next-generation heat exchanger designs that improve thermal efficiency and reduce energy consumption, responding to a growing demand for greener solutions.

Moreover, the surge in electric vehicle production further propels the need for effective thermal management systems, which often rely on advanced heat exchange technologies. The electric vehicle thermal management system market is anticipated to grow at an impressive CAGR of 16.1% from 2025 to 2034. This transition to electric vehicles emphasizes the critical role that heating plate heat exchangers will play in enhancing performance and reliability. The emphasis on sustainable practices combined with the necessity of efficient heat management creates a robust environment for innovation in heat exchanger technologies, positioning them as integral components in various industrial applications for the upcoming years.

The rise of sustainability as a core value in manufacturing practices is reshaping the landscape of heating plate heat exchangers. As global buyers become more environmentally conscious, manufacturers are increasingly adopting eco-friendly materials and production techniques. This shift not only reduces carbon footprints but also aligns with regulatory requirements aimed at minimizing environmental impact. Innovative materials, such as recycled metals and biodegradable composites, are being explored to enhance the sustainability of these essential components in various industries.

Moreover, the integration of energy-efficient designs and technologies is another vital trend influencing manufacturing practices. Advances in computer modeling and simulation allow engineers to optimize heat transfer efficiency while reducing energy consumption during operation. These smart designs not only contribute to lower energy bills for end users but also boost the overall lifecycle sustainability of the heat exchangers. By investing in greener manufacturing processes and focusing on energy efficiency, producers can ensure that their products not only meet current demands but are also prepared for a future where sustainability will be paramount in the marketplace.

As we look towards 2025, advancements in heating plate heat exchanger technology are set to revolutionize the way industries approach heat transfer performance. One of the most significant trends is the integration of advanced materials that enhance thermal conductivity. Innovations such as graphene and carbon nanotubes are being explored for their superior heat transfer capabilities, allowing for more efficient and compact designs. This shift not only improves energy efficiency but also reduces the footprint of heat exchangers in various applications, from food processing to chemical manufacturing.

Moreover, smart technologies are becoming increasingly prevalent in heat exchanger systems. The incorporation of IoT (Internet of Things) devices enables real-time monitoring and predictive maintenance, leading to improved operational reliability and reduced downtime. By harnessing data analytics, organizations can optimize heat transfer processes and adjust parameters dynamically based on specific operational conditions. This technological evolution supports not only better performance but also aligns with sustainability goals, as more efficient systems consume less energy and minimize waste. As global buyers prepare for 2025, understanding these trends will be crucial for making informed purchasing decisions in an increasingly competitive landscape.

As the global plate and frame heat exchanger market is set to grow from USD 7.21 billion in 2025 to USD 10.50 billion by 2030, buyers must navigate both opportunities and challenges in the coming years. The projected CAGR of 7.8% indicates an increasing demand for efficient thermal management solutions across various industries, including HVAC, food and beverage, and chemical processing. Emerging trends in this sector, such as advancements in materials science and innovative design approaches, are likely to enhance the performance and reliability of heat exchangers.

However, global buyers should also be aware of potential obstacles. Supply chain disruptions and fluctuating raw material prices could impact production timelines and costs. Additionally, stringent regulatory requirements aimed at environmental sustainability may pose challenges for manufacturers and buyers alike. To maximize their investments, buyers must stay informed about technological developments and market dynamics while building strategic partnerships to mitigate risks associated with these uncertainties. Embracing these factors will be crucial for success in the evolving landscape of heat exchanger technology.