Leave Your Message

In the realm of modern industrial processes, the significance of Heat Exchanger Parts cannot be overstated. These components are vital for optimizing thermal efficiency and enabling effective heat transfer in various applications, ranging from chemical processing to energy generation. According to a report by MarketsandMarkets, the global heat exchanger market is projected to grow from $15.45 billion in 2020 to $23.95 billion by 2025, indicating a compound annual growth rate (CAGR) of 9.1%. This growth underscores the increasing reliance on advanced heat exchanger technology to meet energy efficiency standards and sustainability goals. As industries continue to evolve and innovate, understanding the essential role played by each component in the heat exchanger system becomes crucial. Proper selection and maintenance of Heat Exchanger Parts can lead to significant cost savings, enhanced performance, and reduced environmental impact—a testament to their indispensable role in modern industrial operations.

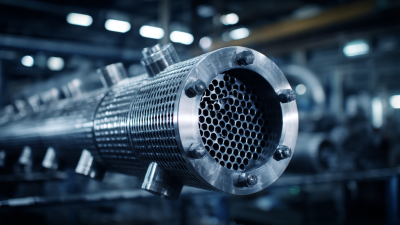

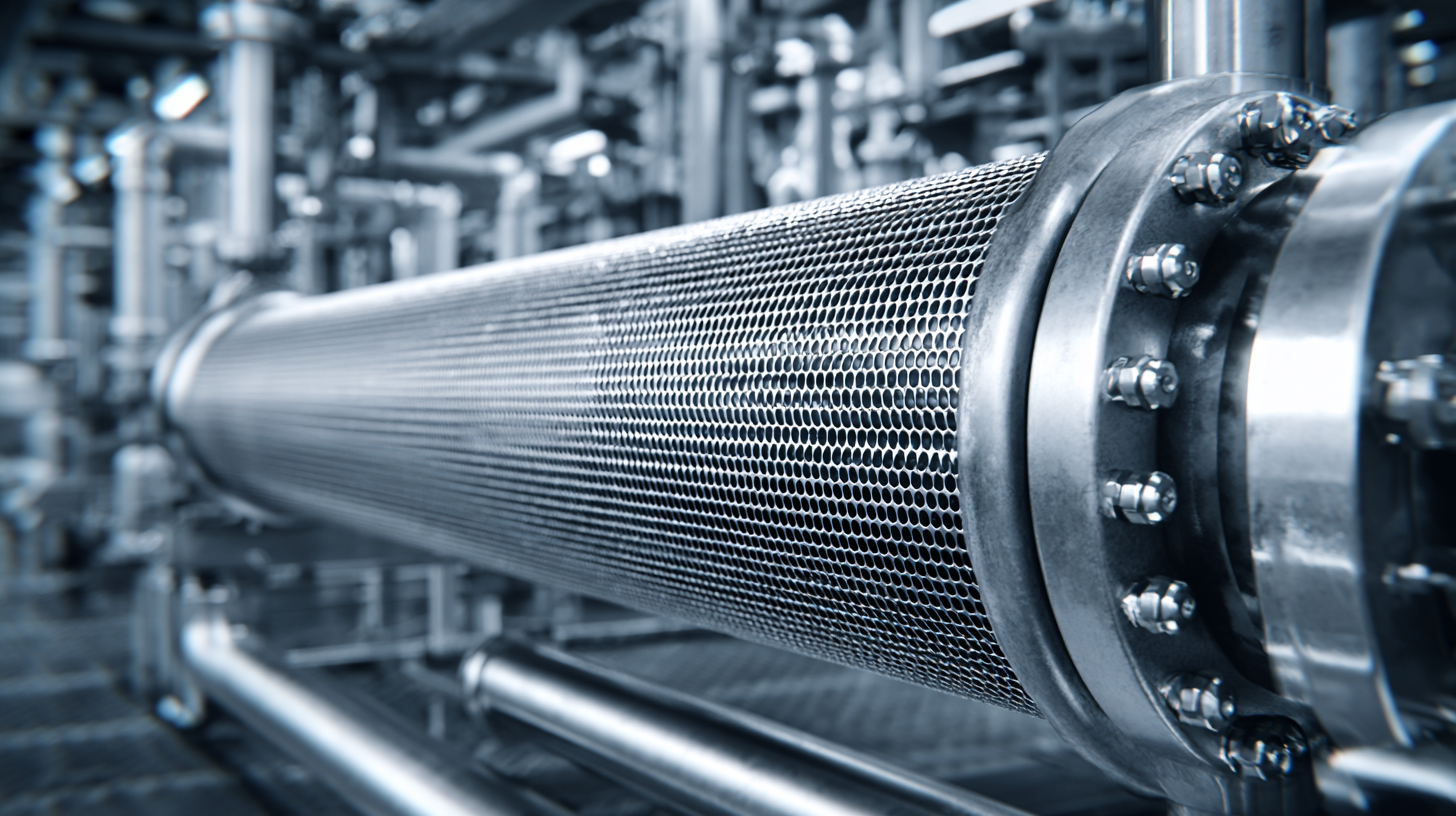

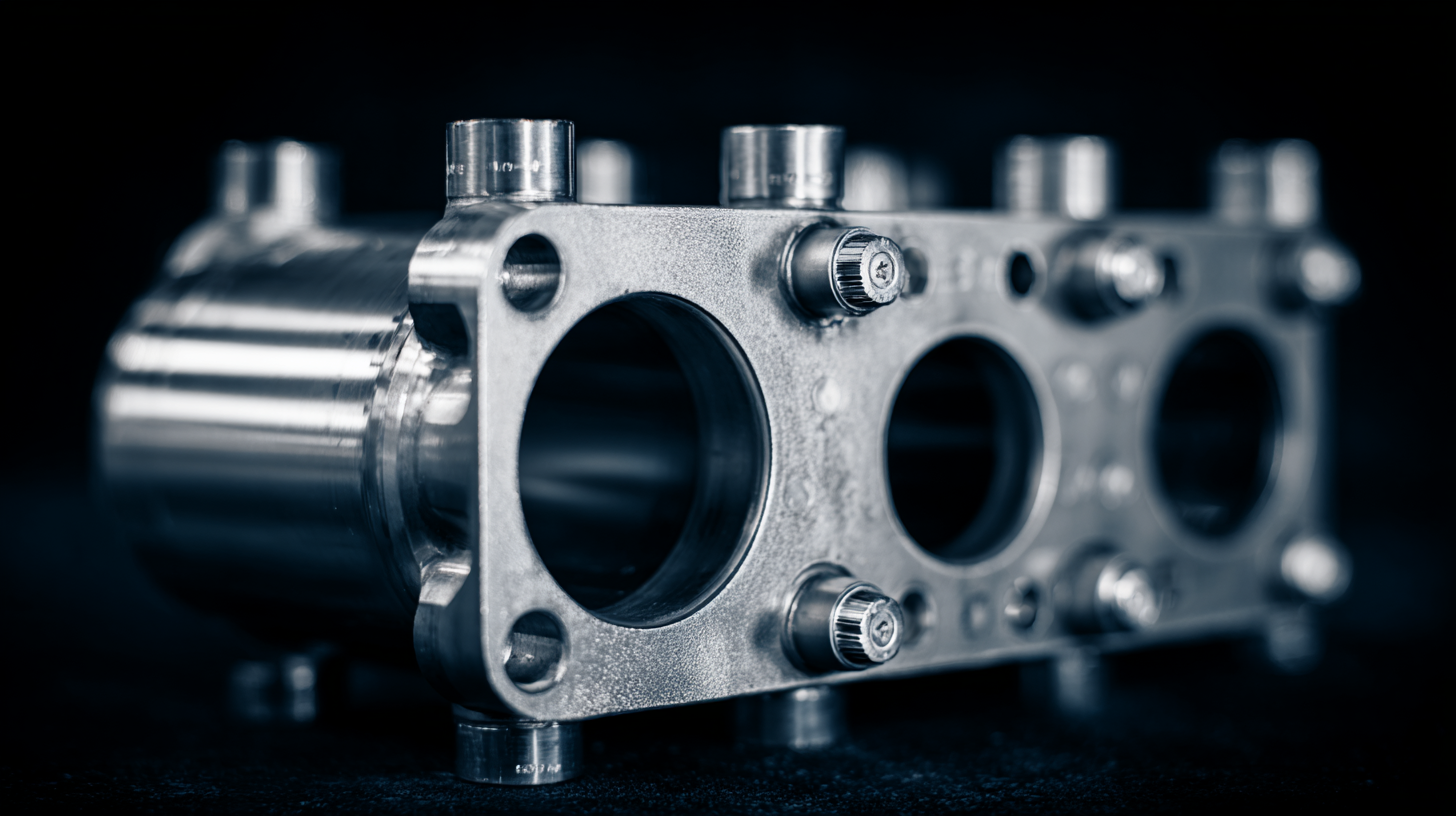

Heat exchangers play a pivotal role in various industrial applications, serving as critical components in maintaining optimal temperature control processes. These devices facilitate the transfer of heat between two or more fluids, which can be in different temperature states, thereby enhancing efficiency in heating and cooling systems. The fundamental parts of heat exchangers, including tubes, plates, and shells, are designed to maximize the surface area for heat transfer while minimizing resistance to fluid flow, ultimately ensuring effective thermal management in industries such as aerospace, automotive, and chemical processing.

In recent years, the market for heat exchangers has seen significant growth due to advancements in technology and increasing industrial demands. As industries evolve, the need for more efficient thermal management solutions becomes paramount. This is reflected in the projections for the spherical aluminum powder market, anticipated to reach $976.4 million by 2033, alongside a steady compound annual growth rate. The importance of robust and reliable heat exchanger components will only increase as sectors like aerospace and defense continue to prioritize sophisticated cooling and heating technologies, underscoring the essential role these parts play in modern industrial operations.

Heat exchangers play an indispensable role across a variety of key industries, fundamentally influencing efficiency and productivity. In the oil and gas sector, for instance, heat exchangers facilitate the cooling of highly heated fluids, enabling safer extraction and processing. According to a report by MarketsandMarkets, the global heat exchanger market in the oil and gas industry is projected to reach USD 22.34 billion by 2025, driven by the increasing demand for energy and the need for efficient thermal management solutions.

In the food processing industry, heat exchangers are crucial for pasteurization and cooling processes, ensuring product safety and quality. The Food and Beverage sector accounted for a significant share of the heat exchanger market, with experts noting a growth rate of approximately 5.3% annually. Upgrading to advanced heat exchanger materials can enhance energy recovery and reduce waste, aligning with the industry's sustainability goals.

Tips: When integrating heat exchangers into industrial processes, consider periodic maintenance to prevent fouling and ensure longevity. Additionally, investing in high-quality materials can enhance thermal efficiency. Moreover, exploring innovative designs like plate heat exchangers can lead to superior heat transfer rates while saving space in your facility.

When considering energy savings in modern industrial applications, the design of heat exchangers plays a pivotal role. An efficient heat exchanger maximizes heat transfer while minimizing energy input, leading to significant cost savings and improved operational efficiency. Factors such as surface area, fluid flow arrangement, and material choice directly influence the efficiency ratings of these critical components. By optimizing these design elements, industries can achieve better heat recovery, reduce energy consumption, and lower greenhouse gas emissions.

**Tips:** To enhance the efficiency of your heat exchanger, consider conducting a thorough analysis of your current system. Implementing advanced technologies, such as computer simulations, can help identify potential improvements in design and operation. Regular maintenance and cleaning of heat exchange surfaces are also crucial for sustaining optimal performance, as fouling can drastically reduce efficiency.

Furthermore, incorporating innovative designs like plate and frame or modular heat exchangers can lead to higher efficiency ratings. These designs provide greater flexibility in terms of installation and maintenance, contributing to long-term energy savings. An effective heat exchanger design not only benefits the environment through energy conservation but also enhances the competitiveness of industries by reducing operational costs.

| Part Name | Material | Efficiency Rating (%) | Typical Applications | Average Lifetime (Years) |

|---|---|---|---|---|

| Tube | Stainless Steel | 90 | Chemical Processing | 10 |

| Plate | Aluminum | 85 | Food Processing | 8 |

| Shell | Carbon Steel | 80 | Oil Refining | 15 |

| Gasket | PTFE | 95 | Pharmaceuticals | 5 |

| Drum | Nickel Alloy | 88 | Power Generation | 20 |

Innovations in heat exchanger parts are driving significant advancements in industrial applications, enhancing efficiency and performance across various sectors. Emerging technologies, such as advanced materials and enhanced design methodologies, are reshaping how heat exchangers operate. For instance, the development of compact heat exchangers allows for better heat transfer efficiency even in limited spaces, making them ideal for modern industrial setups. Similarly, the integration of smart technologies enables real-time monitoring and predictive maintenance, reducing downtime and operational costs.

Tips: When selecting heat exchanger parts, consider materials that offer higher thermal conductivity and resist corrosion. This not only improves efficiency but also extends the lifespan of the equipment. Additionally, staying informed about regulatory standards can help ensure compliance and optimize performance.

Furthermore, sustainability is becoming a vital focus in the innovation of heat exchanger components. Companies are increasingly investing in eco-friendly solutions that minimize energy consumption and reduce emissions. This trend not only meets regulatory demands but also appeals to environmentally conscious consumers, making sustainability a critical component of any modern industrial strategy.

Tips: Evaluate the lifecycle of heat exchanger parts and choose designs that promote energy efficiency. Implementing energy recovery systems within heat exchangers can significantly reduce overall energy use and environmental impact.

Heat exchangers play a crucial role in enhancing the efficiency of industrial systems, particularly in their ability to recover waste heat. This capability not only supports energy efficiency but also significantly reduces the environmental impact associated with excessive energy consumption. Recent studies highlight that waste heat recovery systems can achieve remarkable energy and exergy efficiencies, ultimately contributing to sustainable development goals. The integration of heat exchangers in various industries exemplifies a step towards a more sustainable future, as they optimize energy use and minimize waste.

Tips for improving heat exchanger efficiency include regular maintenance to prevent fouling, which can reduce performance, and considering the implementation of advanced materials that enhance heat transfer capabilities. Additionally, industries should explore hybrid cooling methods that use more sustainable resources, such as seawater, to further mitigate their environmental footprint.

In data centers, where cooling is a major energy consumer, understanding the environmental impacts of different cooling methods 'from cradle to grave' is essential. This comprehensive approach helps businesses evaluate their cooling strategies and make informed decisions that prioritize sustainability without compromising performance. By embedding efficiency at every level, industries can significantly lessen their ecological impact while continuing to innovate.