Leave Your Message

As industries worldwide strive for more sustainable practices and operational efficiency, the importance of advanced technologies such as heat exchangers cannot be overstated. According to a report by the U.S. Department of Energy, heat exchangers are responsible for approximately 70% of the energy loss in industrial processes, costing businesses billions annually. By optimizing heat recovery and enhancing energy efficiency, modern heat exchangers are poised to significantly reduce energy consumption and minimize environmental impact.

Furthermore, with the global heat exchanger market projected to reach USD 25 billion by 2026, it is evident that the innovation in this sector will play a critical role in transforming energy savings. As we delve into the future of efficient heat exchangers, we explore how cutting-edge designs and materials can lead to greater manufacturing excellence, promoting a paradigm shift towards energy-efficient operations across industries, and ultimately serving the global market from the strong manufacturing base of China.

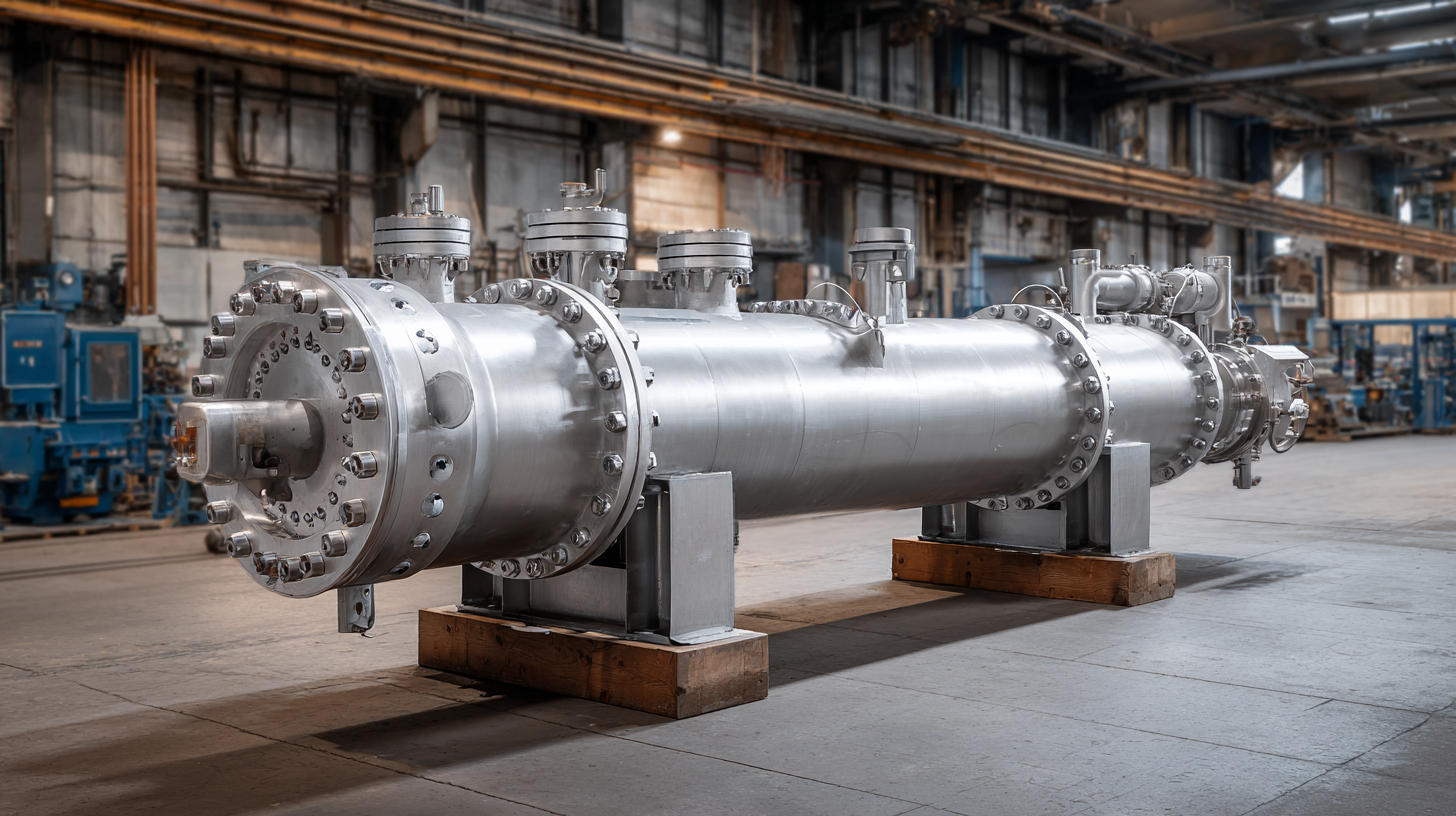

The evolution of heat exchanger technology has significantly influenced industrial applications, driving innovations that enhance energy efficiency. Over the decades, heat exchangers have transitioned from basic designs to sophisticated systems that leverage advanced materials and intelligent controls. Emerging technologies, such as microchannel heat exchangers and enhanced surface designs, have provided greater heat transfer rates while reducing the footprint of these critical devices. This transformation not only optimizes resource usage but also minimizes operational costs, making industries more sustainable.

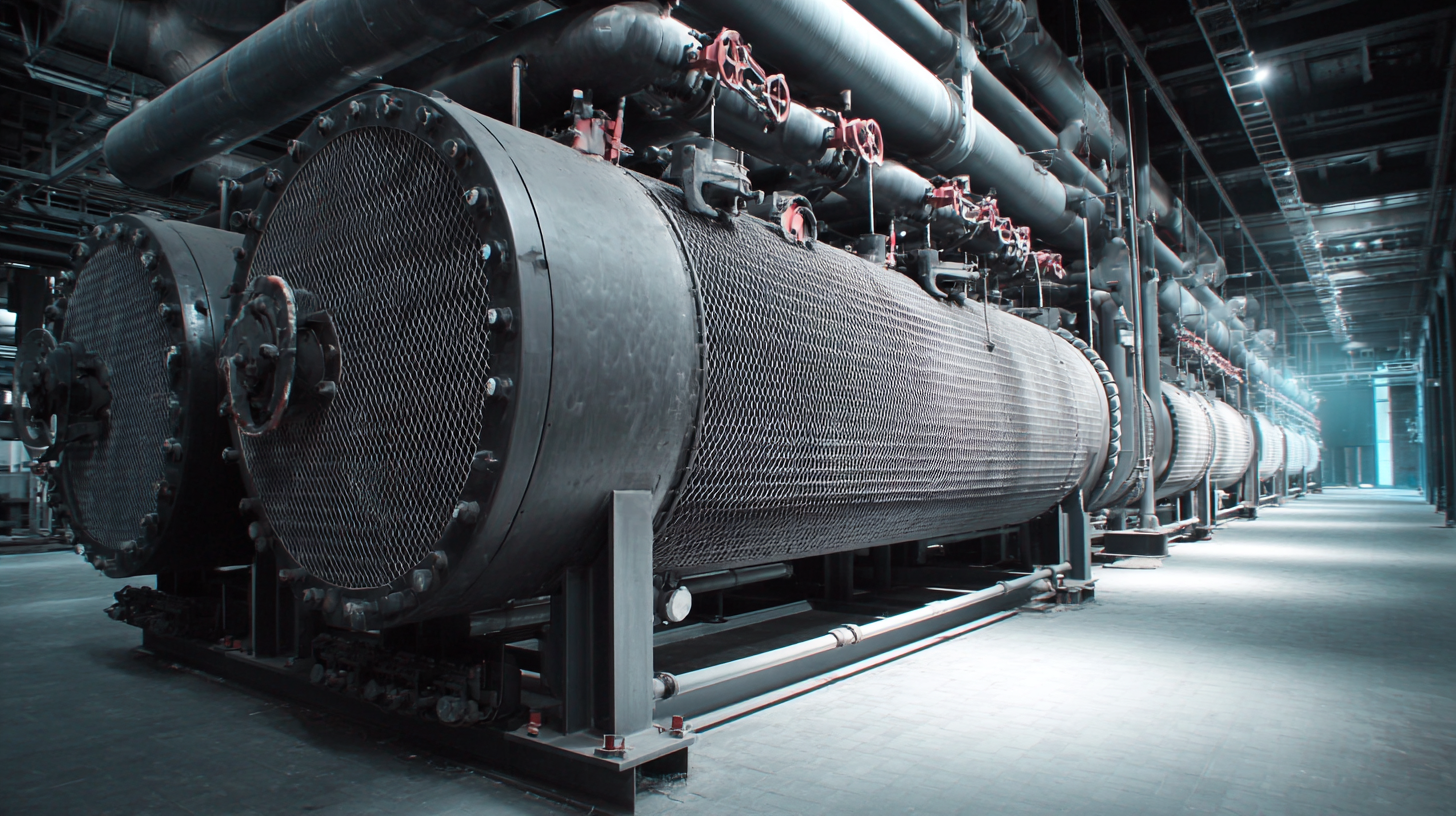

Furthermore, the integration of digital technologies into heat exchanger systems marks a pivotal evolution in maintaining efficiency. Predictive maintenance and real-time monitoring capabilities enable industries to anticipate performance issues before they escalate, thereby reducing downtime and enhancing reliability. As industries increasingly prioritize sustainability and energy savings, the demand for innovative heat exchanger solutions will continue to grow, paving the way for future advancements that will redefine operational efficiencies and environmental stewardship.

Innovative materials are revolutionizing the design and efficiency of heat exchangers, leading to significant energy savings in various industrial applications. Traditional materials such as copper and aluminum have long dominated the market, but the emergence of advanced composite materials and metal foams is paving the way for better performance. According to a report by MarketsandMarkets, the global heat exchanger market is projected to reach USD 28.2 billion by 2026, driven in part by technological advancements in materials that enhance thermal management and durability.

These innovative materials provide higher thermal conductivity and improved corrosion resistance, which are crucial for maintaining efficiency in demanding environments. For instance, the use of carbon-based composites has been shown to increase heat transfer rates by up to 30% compared to conventional materials. Additionally, new manufacturing techniques, such as additive manufacturing, allow for the creation of complex geometries that optimize fluid flow and minimize pressure drops, further enhancing overall energy efficiency. The integration of these novel materials into heat exchanger design exemplifies how innovation can lead to substantial reductions in energy consumption, underlining the industry's shift towards more sustainable and cost-effective solutions.

| Material Type | Thermal Conductivity (W/m·K) | Corrosion Resistance | Weight (kg/m²) | Energy Savings (%) |

|---|---|---|---|---|

| Copper | 385 | High | 2.0 | 30 |

| Aluminum | 205 | Moderate | 1.5 | 25 |

| Stainless Steel | 16 | Very High | 3.0 | 15 |

| Titanium | 21 | Excellent | 4.5 | 20 |

| Graphene | 1000 | Good | 0.5 | 40 |

The integration of Internet of Things (IoT) technology into smart heat exchange systems is revolutionizing energy management across various industries. By embedding sensors and connectivity in heat exchangers, companies can collect real-time data on temperature, pressure, and flow rates. This data-driven approach allows for more precise monitoring of system performance, enabling operators to optimize energy usage effectively. Such enhancements not only lead to significant energy savings but also contribute to improved equipment longevity by identifying potential inefficiencies before they escalate into major issues.

Moreover, smart heat exchange systems facilitate predictive maintenance, which is crucial for industrial operations. With IoT technology, algorithms can analyze historical data to forecast when a heat exchanger might need servicing, reducing unexpected downtime and maintenance costs. This proactive management ensures that resources are utilized efficiently, aligning with broader sustainability goals. As industries strive to minimize their ecological footprint, the adoption of IoT-enabled heat exchangers is an essential step toward achieving enhanced energy management and operational excellence.

This chart illustrates the projected energy savings from the implementation of smart heat exchange systems integrated with IoT technologies in various industrial sectors over the next five years.

The manufacturing and operation of heat exchangers are undergoing a significant transformation driven by sustainability trends. As industries increasingly recognize the impact of their energy consumption on the environment, the push for more efficient heat exchange processes has never been more critical. Modern heat exchangers are being designed with materials and technologies that maximize efficiency while minimizing waste. Innovations such as advanced materials that enhance thermal conductivity and designs that optimize fluid flow are at the forefront of this movement, leading to substantial energy savings and reduced carbon footprints.

In addition to manufacturing improvements, the operational phase of heat exchangers is also seeing a shift towards sustainability. Smart monitoring systems are being integrated to track performance in real-time, allowing for predictive maintenance that reduces downtime and energy waste. Moreover, the adoption of renewable energy sources to operate heat exchangers is gaining traction, aligning with global sustainability goals. These practices not only improve overall energy efficiency but also foster a circular economy approach, where waste heat is repurposed, contributing to the sustainability of industrial operations. As these trends continue to evolve, the future of heat exchangers looks promising in promoting a greener and more energy-efficient industrial landscape.

Regulatory policies play a pivotal role in shaping the future of heat exchange solutions, particularly in driving efficiency and energy savings across various industries. According to a recent report by the International Energy Agency (IEA), industrial heat exchangers account for approximately 10-15% of total industrial energy consumption. This statistic underscores the importance of optimizing these systems not just for compliance but for substantial cost savings. As governments implement stricter energy efficiency regulations, industries are increasingly pressured to adopt advanced heat exchanger technologies that minimize energy loss and adapt to sustainable practices.

Tip: Consider conducting a thorough energy audit to identify areas where heat exchange efficiency can be improved. This process can reveal potential upgrades, such as improving insulation or replacing outdated exchangers with high-efficiency models.

Furthermore, the integration of regulatory incentives, such as tax credits and grants for energy-efficient upgrades, is encouraging industries to invest in better heat exchange solutions. The U.S. Department of Energy estimates that enhancing heat exchanger performance could lead to energy savings of up to 30% in many sectors. As regulations continue to evolve, companies that proactively adapt their heat exchange systems will not only comply with legal standards but also enhance their competitiveness in an increasingly eco-conscious market.

Tip: Stay informed about local and national energy regulations that may affect your business, and explore available incentives for upgrading to more efficient technologies.