Leave Your Message

When it comes to optimizing operational efficiency in various industrial applications, selecting the right heat exchanger parts is crucial. According to a recent report by MarketsandMarkets, the global heat exchanger market is projected to grow from USD 15.85 billion in 2020 to USD 21.60 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.3%. This growth is largely driven by increasing energy demands and the expanding use of heat exchangers in sectors such as oil and gas, chemical processing, and HVAC systems. However, the effectiveness of heat exchangers is significantly influenced by the quality and compatibility of their components.

Understanding the various types of heat exchanger parts, their functions, and selection criteria can be a game changer in enhancing heat transfer efficiency and reducing operational costs. This guide aims to empower manufacturers and engineers with the essential knowledge needed to select the best heat exchanger parts tailored to meet their specific needs.

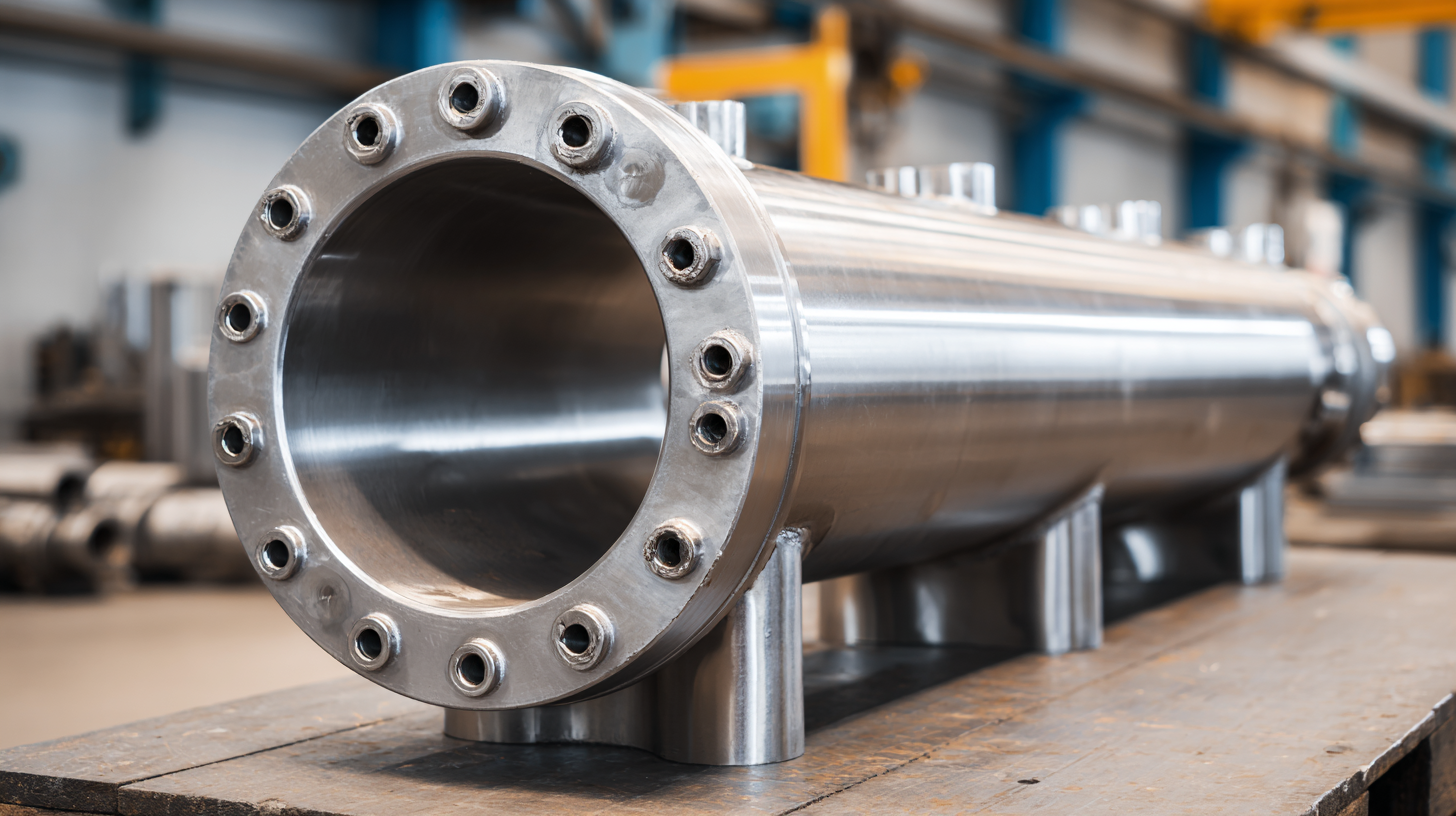

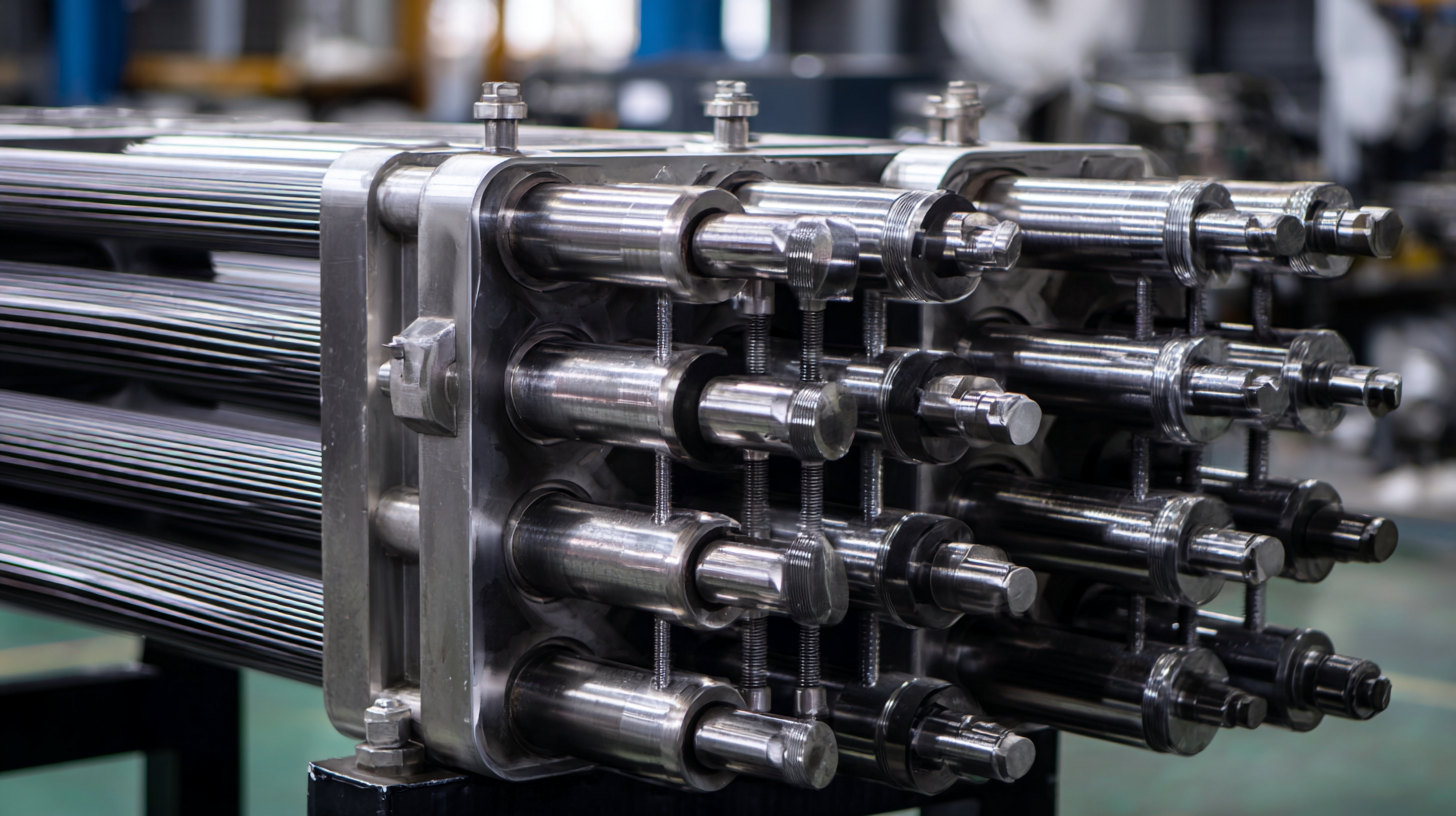

When selecting heat exchanger parts, understanding the various types and their unique features is crucial. Heat exchangers primarily fall into categories such as shell-and-tube, plate, and air-cooled designs. Shell-and-tube exchangers consist of a series of tubes housed within a cylindrical shell, allowing for effective heat transfer between fluids. They are highly versatile, often utilized in industries like oil and gas, chemical processing, and power generation due to their ability to handle high pressures and temperatures.

Plate heat exchangers, on the other hand, are composed of multiple thin plates stacked together to create channels for fluid flow. This design maximizes the surface area for heat transfer, making them ideal for food processing, pharmaceuticals, and HVAC applications where space is limited. Air-cooled heat exchangers utilize ambient air to cool the working fluid, making them suitable for situations where water is scarce. Each of these types features distinct advantages and is selected based on specific application requirements, including thermal performance, space constraints, and maintenance considerations. Understanding these key characteristics aids in selecting the right components to optimize efficiency and reliability in thermal management systems.

When selecting heat exchanger components, understanding essential specifications is crucial to optimize performance and efficiency. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), thermal efficiency can be significantly enhanced when components are tailored to specific applications.

Key specifications include the material selection, which should allow for high thermal conductivity and resistance to corrosion. Common choices like stainless steel or copper can impact the overall efficiency and lifespan of the heat exchanger.

Another vital specification is the design type. Shell-and-tube and plate heat exchangers, for example, offer different advantages depending on the application. A study by the Heat Exchange Institute (HEI) indicates that using the appropriate design can improve heat transfer efficiency by up to 30%.

Additionally, flow arrangement—counterflow versus parallel flow—plays a significant role. Counterflow configurations allow for more efficient heat transfer due to the temperature gradient maintained throughout the heat exchange process. By focusing on these essential specifications, businesses can ensure that their heat exchangers meet industry standards and operational demands efficiently.

Selecting the right material for heat exchanger parts is crucial for optimizing efficiency and longevity. The performance of a heat exchanger largely depends on the thermal conductivity and corrosion resistance of its components. For instance, materials such as stainless steel and titanium are often favored for their ability to withstand high temperatures and pressure while resisting oxidation and corrosion. Understanding the specific application and environment in which the heat exchanger will operate is essential for making informed material choices.

Another important factor to consider is the compatibility of the selected material with the fluids being processed. For example, if the heat exchanger is intended for use in a chemical processing facility, selecting materials that can withstand acidic or caustic substances is imperative. Additionally, the thermal expansion characteristics of the material can impact performance; hence, choosing materials with similar thermal expansion rates as other system components can minimize stress and potential failure. Evaluating these aspects will help maximize the efficiency and longevity of your heat exchanger, ensuring reliable performance over time.

When selecting heat exchanger parts, avoiding common pitfalls can significantly enhance your system's efficiency and longevity. One prevalent mistake is failing to consider compatibility with existing equipment. Each heat exchanger operates under specific conditions, and neglecting to match the new components with the current setup can lead to operational failures and costly repairs. Ensure to meticulously review the specifications and operational requirements of your system before making any purchases.

Another common error is overlooking the importance of quality materials. Many buyers are tempted to go for the cheapest options, but inferior materials can compromise performance and safety. Heat exchangers often operate in challenging environments, and substandard parts can result in corrosion, leaks, or even catastrophic failures. Prioritizing parts made from high-quality, resistant materials will save time and money in the long run, reducing the likelihood of unforeseen maintenance issues. Additionally, always request documentation and certifications to ensure that the parts meet industry standards.

In an ever-evolving industrial landscape, the future of heat exchanger technology and design is characterized by increased efficiency and sustainability. As industries face mounting pressure to minimize their environmental impact, manufacturers are innovating to create heat exchangers that consume less energy and reduce emissions. Emerging technologies, such as advanced materials and 3D printing, are paving the way for lighter, more compact designs that enhance heat transfer while also increasing durability. These advancements not only improve operational efficiency but also extend the lifespan of heat exchanger components, which is crucial for industries that rely on consistent performance.

Moreover, the integration of smart technology into heat exchangers is set to revolutionize maintenance and monitoring practices. IoT-enabled sensors can provide real-time data on system performance, allowing for predictive maintenance and reducing downtime. This trend towards smart systems is not just about enhancing efficiency, but also about enabling companies to make informed decisions based on analytics. As heat exchanger design continues to adapt to these exciting trends, the focus will remain on creating solutions that not only meet current needs but also anticipate future challenges in a rapidly changing industrial environment.