Leave Your Message

In the realm of thermal management, the selection of the right Heat Exchanger Phe plays a crucial role in ensuring maximum efficiency and performance for industrial applications. As industries continue to evolve and the demand for energy efficiency becomes increasingly critical, understanding the nuances of heat exchanger design and operation is essential. This ultimate guide aims to equip you with valuable insights and actionable tips for selecting the most suitable Heat Exchanger Phe for your specific needs.

From assessing the thermal loads to understanding fluid dynamics and material compatibility, we will explore key considerations that drive optimal performance. Whether you are an engineer, a procurement specialist, or simply interested in enhancing your system's efficiency, this guide serves as a comprehensive resource to navigate the complexities of heat exchanger selection and ensure your operations run smoothly.

When selecting Plate Heat Exchangers (PHE) to achieve optimal efficiency, it's crucial to evaluate several key factors that directly impact performance. One of the primary considerations is the type of fluids being exchanged and their respective temperatures. Understanding the thermal properties of the fluids helps in choosing the right materials and configurations for the heat exchanger. Additionally, the flow arrangement—counterflow, parallel flow, or crossflow—can significantly influence the effectiveness of heat transfer. Selecting an arrangement that maximizes the temperature gradient between the hot and cold fluids is essential for enhancing overall efficiency.

In the context of modern energy challenges, integrating energy-efficient heating systems can greatly benefit both performance and sustainability. As commercial properties increasingly face pressure to meet Minimum Energy Efficiency Standards (MEES), choosing the right PHE can play a pivotal role. With a growing trend towards electric heat pumps as a sustainable alternative, heat exchangers need to be compatible with evolving technologies. Furthermore, features like enhanced thermal conductivity are becoming vital, as they contribute to better energy conversion efficiencies. By prioritizing these factors, businesses can improve their heating solutions while reducing their carbon footprint, aligning with global efforts to decarbonize the built environment.

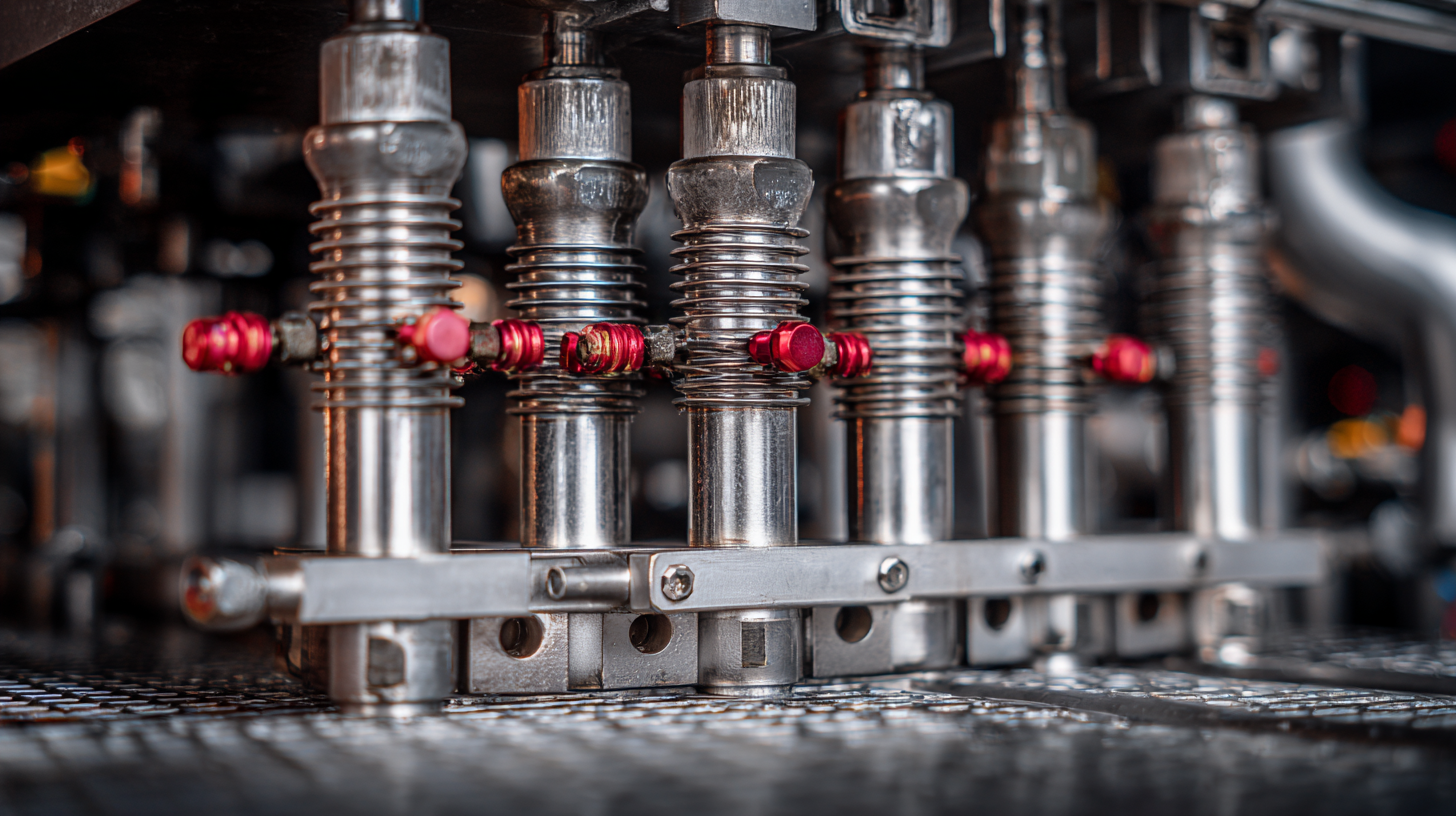

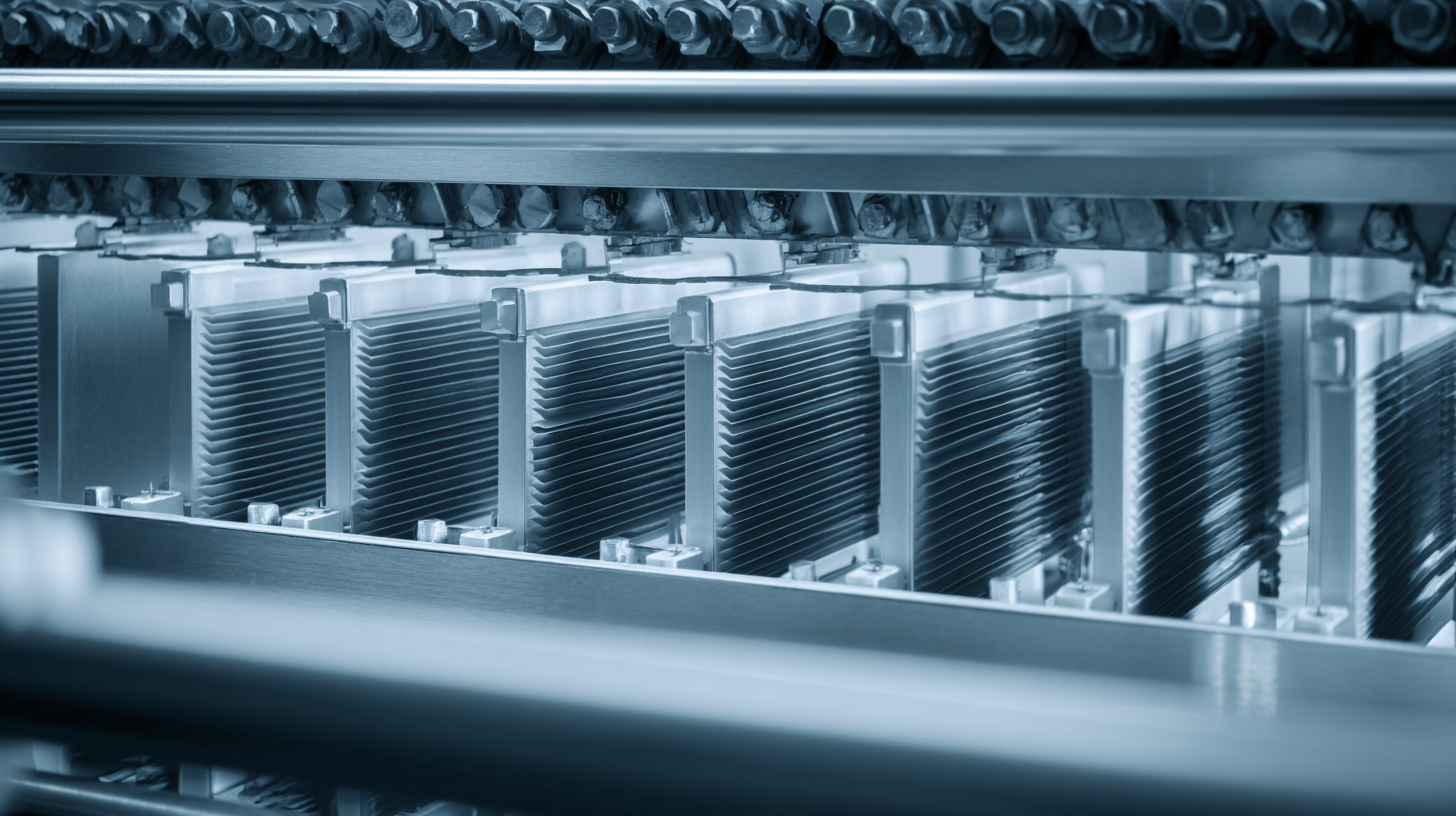

When selecting a Plate Heat Exchanger (PHE) for diverse applications, understanding the types available can significantly enhance both efficiency and performance. Among the top five types, the traditional all-stainless steel PHE is favored for its robustness and ability to handle high temperatures, making it ideal for chemical and food processing industries. On the other hand, the printed circuit heat exchanger (PCHE) stands out due to its lightweight design and high heat transfer density, allowing for space-saving applications in energy-intensive sectors.

Recent advancements, such as the incorporation of nanofluids like silicon carbide, have further optimized thermal performance in PHEs. With an optimal concentration of 0.60%, these novel stabilized fluids demonstrate enhanced heat transfer capabilities. Additionally, the impact of plate spacing and inclination angles on thermal performance emphasizes the necessity of tailored designs in line with specific operational demands. Furthermore, evaluating different U-shaped designs in applications like parabolic trough solar collectors illustrates how innovative engineering can lead to improved thermal management, enhancing both efficiency and energy use in various systems.

Understanding heat transfer principles is crucial when designing heat exchanger PHEs (Plate Heat Exchangers) to maximize efficiency and performance. The effectiveness of a heat exchanger largely depends on its ability to facilitate heat transfer between the two fluids without mixing them. Therefore, selecting materials with high thermal conductivity and appropriate surface areas is essential. The design must also consider flow arrangement, whether it’s counterflow, parallel flow, or crossflow, as these configurations significantly influence the thermal performance and operational efficiency.

Additionally, optimizing the design involves minimizing pressure drops and ensuring that the temperature differences between the fluids are maximized. This can be achieved by appropriately sizing the plates and channels, enabling better flow distribution. Incorporating features like turbulent flow can enhance the heat transfer rate, making the system more efficient. Focusing on these design choices not only leads to improved energy efficiency but also contributes to enhanced reliability and longevity of the heat exchanger equipment, ultimately delivering better performance in various applications.

| Parameter | Value | Unit | Impact on Efficiency |

|---|---|---|---|

| Heat Transfer Area | 200 | m² | Increases heat transfer efficiency |

| Overall Heat Transfer Coefficient | 500 | W/m²·K | Higher values lead to better performance |

| Inlet Temperature (Hot Stream) | 150 | °C | Higher inlet temperature can improve heat recovery |

| Inlet Temperature (Cold Stream) | 30 | °C | Lower inlet temperature can increase efficiency |

| Flow Arrangement | Counterflow | - | Maximizes temperature difference and efficiency |

| Pressure Drop (Hot Side) | 20 | kPa | Excessive drop can reduce flow rates and efficiency |

| Pressure Drop (Cold Side) | 15 | kPa | Should be minimized for better performance |

When selecting Plate Heat Exchangers (PHEs) for industrial applications, avoiding common pitfalls can significantly impact system efficiency and performance. One prevalent mistake is underestimating the importance of fluid properties. According to a recent study by the Heat Transfer Research Institute, failure to consider viscosity and thermal conductivity can lead to a 20-30% decrease in heat transfer efficiency. Properly understanding these properties allows for optimal design and configuration of the PHE, ensuring better heat exchange rates.

Another critical error is neglecting fouling factors during the selection process. The International Journal of Thermal Sciences reported that neglecting to account for potential fouling can result in a loss of up to 40% in thermal performance over time. Selecting PHEs with appropriate materials and surface treatments tailored to the specific process conditions can mitigate fouling effects, extending the service life of the equipment and maintaining operational efficiency. By focusing on these common mistakes, engineers can improve their heat exchanger selection processes, leading to enhanced industrial performance.

When evaluating the maintenance needs of heat exchangers, particularly in the context of geothermal energy systems, understanding their performance under varying operational conditions is key. Recent studies show that thermal performance evaluation methods, such as those applied to double pipe heat exchangers in biomass gasification systems, can provide critical insights into the efficiency of these systems. For instance, a comparative analysis of two integrated collector-storage (ICS) systems highlighted the effectiveness of thermosyphon systems, demonstrating significant daily thermal performance improvements. This underscores the importance of regular monitoring and maintenance to ensure consistent performance.

When evaluating the maintenance needs of heat exchangers, particularly in the context of geothermal energy systems, understanding their performance under varying operational conditions is key. Recent studies show that thermal performance evaluation methods, such as those applied to double pipe heat exchangers in biomass gasification systems, can provide critical insights into the efficiency of these systems. For instance, a comparative analysis of two integrated collector-storage (ICS) systems highlighted the effectiveness of thermosyphon systems, demonstrating significant daily thermal performance improvements. This underscores the importance of regular monitoring and maintenance to ensure consistent performance.

Moreover, advancements in ground source heat pump (GSHP) technologies for cold climates reveal that optimized maintenance strategies can extend the longevity of these systems, significantly enhancing their performance. Comprehensive reviews indicate that an effective maintenance regimen, guided by systematic methodologies, not only minimizes downtime but also maximizes operational efficiency. Investing in such evaluations and maintenance practices is crucial for achieving sustainable and efficient building heating and cooling solutions, especially as geothermal energy continues to gain traction in the renewable energy landscape.