Leave Your Message

Heat Exchanger Maintenance is a critical aspect of ensuring the efficiency and longevity of thermal systems across various industries. According to a recent report by the Heat Exchanger Industry Association, improper maintenance can lead to efficiency losses of up to 20%, significantly increasing operational costs and downtime. As heat exchangers play a pivotal role in processes such as cooling, heating, and energy recovery, understanding common maintenance issues and their solutions becomes essential for facility operations. The National Association of Corrosion Engineers also highlights that nearly 30% of heat exchanger failures are attributed to inadequate maintenance practices. Through effective monitoring, cleaning, and timely repairs, organizations can not only enhance performance but also extend the lifespan of their heat exchangers, resulting in substantial savings and improved reliability.

This blog will explore some of the most prevalent heat exchanger maintenance challenges and provide practical solutions to optimize functionality.

Heat exchangers play a crucial role in various industries by transferring heat between two or more fluids. However, these systems often face common maintenance issues that can lead to inefficiencies and costly downtime. One significant problem is fouling, which occurs when unwanted materials accumulate on the heat transfer surfaces. This buildup reduces heat transfer efficiency and can increase operational costs.

Regular cleaning and using appropriate filtration methods can help mitigate this issue, but in some cases, switching to more resistant materials or advanced designs may be necessary to enhance performance.

Heat exchangers play a crucial role in various industries by transferring heat between two or more fluids. However, these systems often face common maintenance issues that can lead to inefficiencies and costly downtime. One significant problem is fouling, which occurs when unwanted materials accumulate on the heat transfer surfaces. This buildup reduces heat transfer efficiency and can increase operational costs.

Regular cleaning and using appropriate filtration methods can help mitigate this issue, but in some cases, switching to more resistant materials or advanced designs may be necessary to enhance performance.

Another prevalent issue is corrosion, which can compromise the integrity of heat exchangers over time. Corrosion is often exacerbated by the type of fluids being used and environmental conditions. Employing coatings or selecting corrosion-resistant alloys can serve as effective alternatives to extend the lifespan of the heat exchanger. Additionally, monitoring systems can be implemented to detect early signs of corrosion, allowing for timely intervention. By understanding these common challenges and exploring the available alternatives, maintenance teams can significantly improve the reliability and efficiency of heat exchange systems.

Fouling is a significant challenge in the effective operation of heat exchangers, leading to a notable decline in their heat transfer efficiency over time. Various parameters contribute to fouling, including the nature of the fluids being processed and their temperatures. In particular, the deposition of hard crystals or complex organic mixtures can create robust layers that are difficult to remove. For instance, in food processing applications, deposits are often a composite of different substances, which complicates the cleaning process.

Effective cleaning techniques are crucial for maintaining the performance of heat exchangers. Techniques such as mechanical cleaning, chemical treatments, and the use of advanced detergents are critical in addressing the fouling issues. Research has shown that the formulation of cleaning agents significantly impacts their ability to remove deposits effectively. This is particularly evident in applications involving milk, where the cleaning strategy must consider the unique fouling behaviors exhibited at elevated temperatures. By optimizing these cleaning methods, operators can substantially enhance the operational lifespan and efficiency of heat exchangers, minimizing downtime and ensuring reliable performance in various industrial applications.

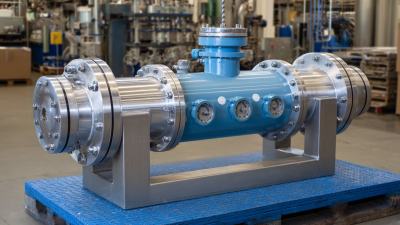

Innovative heat exchanger designs play a crucial role in enhancing energy efficiency and reducing operational costs across various industrial applications. Traditional heat exchangers can suffer from inefficiencies due to fouling and temperature limitations, which often result in increased maintenance needs and reduced lifespan. Recent studies indicate that advanced designs, such as plate-and-frame heat exchangers and spiral heat exchangers, can improve heat transfer rates by up to 30% compared to conventional shell-and-tube models. This efficiency not only saves energy but also minimizes the needed maintenance, as these designs allow for easier cleaning and inspection.

Another promising alternative is the use of compact heat exchangers, which can occupy up to 70% less space than traditional designs without compromising on performance. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), these compact solutions are particularly beneficial in the rapidly evolving fields of renewable energy and HVAC systems. By integrating innovative materials such as graphene or enhanced surface coatings, modern heat exchangers can withstand higher pressures and corrosive environments, further elevating their lifespan and reliability. With these advancements, industries are increasingly leaning towards tailored heat exchanger solutions that align with specific operational challenges, ultimately contributing to more sustainable practices in the field.

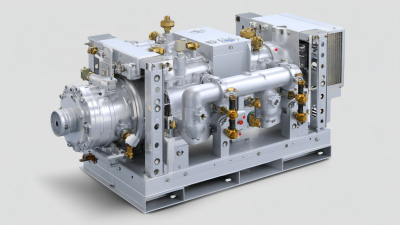

Corrosion is one of the most prevalent issues affecting heat exchangers, leading to significant downtime and increased maintenance costs. According to a study by the National Association of Corrosion Engineers (NACE), corrosion costs the U.S. economy approximately $1 trillion annually, impacting various industries, including oil and gas, power generation, and chemical manufacturing. To combat this challenge, many facilities are turning to alternative materials specifically designed to resist corrosion, such as duplex stainless steels and titanium alloys. These materials offer improved longevity and reliability, ultimately reducing the frequency of replacements and repairs.

In addition to selecting corrosion-resistant materials, implementing protective methods can further enhance the lifecycle of heat exchangers. Techniques such as cathodic protection and the application of anti-corrosive coatings can significantly mitigate the corrosive effects of the process fluids used. A report by the American Society of Mechanical Engineers (ASME) indicates that facilities utilizing these protective measures can experience a decrease in corrosion-related maintenance by up to 40%. Adopting a multifaceted approach, including both material selection and protective technologies, is crucial for optimizing heat exchanger performance while minimizing costly maintenance issues.

In the quest for energy efficiency, maintaining heat exchangers is increasingly recognized as a critical factor in reducing energy consumption across various sectors, from residential to industrial applications. Evaluating energy efficiency in heat exchanger maintenance solutions involves integrating innovative technologies, such as thermal-driven dehumidification systems, which have shown promise in enhancing moisture control while optimizing energy usage. Recent advancements highlight the importance of adopting alternative approaches, such as lower-temperature heating integration in existing building stocks, paving the way for energy renovations that not only improve performance but also align with sustainability goals.

Furthermore, the move towards nature-based solutions, like green roofs, emphasizes a holistic approach to enhancing urban sustainability. These systems can effectively mitigate urban heat islands while contributing to overall energy efficiency. By integrating diverse strategies—such as industrial heat pumps and energy storage technologies—stakeholders can create resilient infrastructures that adapt to climate challenges and optimize energy resources. Such multifaceted evaluations are essential for paving the future of energy-efficient heat exchanger maintenance, driving progress in not only economic performance but also environmental responsibility.