Leave Your Message

In the realm of industrial processes, the efficiency of thermal management is crucial, and one key component that stands out is the Heat Exchanger Phe (Plate Heat Exchanger). According to a recent market report by Research and Markets, the global plate heat exchanger market is projected to grow at a CAGR of 9.5% from 2021 to 2028, driven by increasing demand across various sectors, including HVAC, food and beverage, and chemical processing. The Heat Exchanger Phe offers superior thermal performance due to its compact design, enhancing heat transfer efficiency while minimizing space requirements. Furthermore, advancements in technology and materials are leading to improved durability and lower maintenance costs, making these systems indispensable in modern industrial applications. As industries strive for sustainability and energy efficiency, understanding the fundamentals of Heat Exchanger Phe becomes paramount to optimizing operations and reducing environmental impact.

In the realm of industrial processes, the efficiency of thermal management is crucial, and one key component that stands out is the Heat Exchanger Phe (Plate Heat Exchanger). According to a recent market report by Research and Markets, the global plate heat exchanger market is projected to grow at a CAGR of 9.5% from 2021 to 2028, driven by increasing demand across various sectors, including HVAC, food and beverage, and chemical processing. The Heat Exchanger Phe offers superior thermal performance due to its compact design, enhancing heat transfer efficiency while minimizing space requirements. Furthermore, advancements in technology and materials are leading to improved durability and lower maintenance costs, making these systems indispensable in modern industrial applications. As industries strive for sustainability and energy efficiency, understanding the fundamentals of Heat Exchanger Phe becomes paramount to optimizing operations and reducing environmental impact.

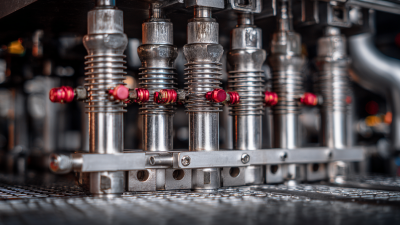

A Plate Heat Exchanger (PHE) is a vital component widely used in various industries for efficient heat transfer processes. It consists of multiple plates arranged in a stack, allowing one fluid to flow on one side and another fluid on the opposite side. The key components of a PHE include the plates, gaskets, and the frame, all of which work together to maximize the surface area for heat transfer and ensure minimal leakage between fluids.

A Plate Heat Exchanger (PHE) is a vital component widely used in various industries for efficient heat transfer processes. It consists of multiple plates arranged in a stack, allowing one fluid to flow on one side and another fluid on the opposite side. The key components of a PHE include the plates, gaskets, and the frame, all of which work together to maximize the surface area for heat transfer and ensure minimal leakage between fluids.

One of the significant advantages of PHEs is their compact design, which facilitates high heat transfer rates while minimizing energy consumption. Recent advancements in technology, including innovative designs featuring twisted tubes and graphene-coated surfaces, are enhancing the performance of conventional heat exchangers. Tips for choosing the right PHE involve considering factors such as the type of fluid, temperature, and pressure requirements, as well as maintenance protocols to minimize fouling, which can significantly affect efficiency.

As businesses look for sustainable solutions, the demand for enhanced heat exchanger technologies is on the rise. The plate heat exchanger market is projected to grow, driven by trends such as the integration of artificial intelligence for predictive maintenance, which helps extend the lifespan of heat exchangers and optimize overall system performance. These developments reflect a shift towards more efficient and environmentally friendly industrial processes.

Plate heat exchangers (PHE) are widely utilized in various industries due to their efficiency and compact design. The working principle of a plate heat exchanger is based on the transfer of heat between two fluids while keeping them separated. The core component consists of multiple thin plates stacked together, creating channels for the two fluids to flow. This arrangement increases the surface area for heat transfer, enabling effective thermal exchange even at lower flow rates.

As fluids pass through the designated channels of the PHE, heat is transferred from the hot fluid to the cold fluid, resulting in a rise in temperature of the cold fluid and a drop in temperature of the hot fluid. The design of these plates allows for turbulent flow, which enhances heat transfer coefficients by disrupting the boundary layer formation on the plate surfaces. Understanding this principle is crucial for industries looking to optimize thermal efficiency in processes such as heating, cooling, and energy recovery, making plate heat exchangers a vital component in modern engineering applications.

| Dimension | Description | Application | Efficiency (%) |

|---|---|---|---|

| Heat Transfer Area | Surface area for heat exchange | Chemical Processing | 85% |

| Flow Configuration | Type of flow arrangement (counterflow, parallel flow) | Food Processing | 90% |

| Temperature Efficiency | Difference in temperature between inlet and outlet | HVAC Systems | 92% |

| Pressure Drop | Loss of pressure across the heat exchanger | Power Generation | 87% |

| Material Types | Materials used (stainless steel, titanium) | Marine Applications | 88% |

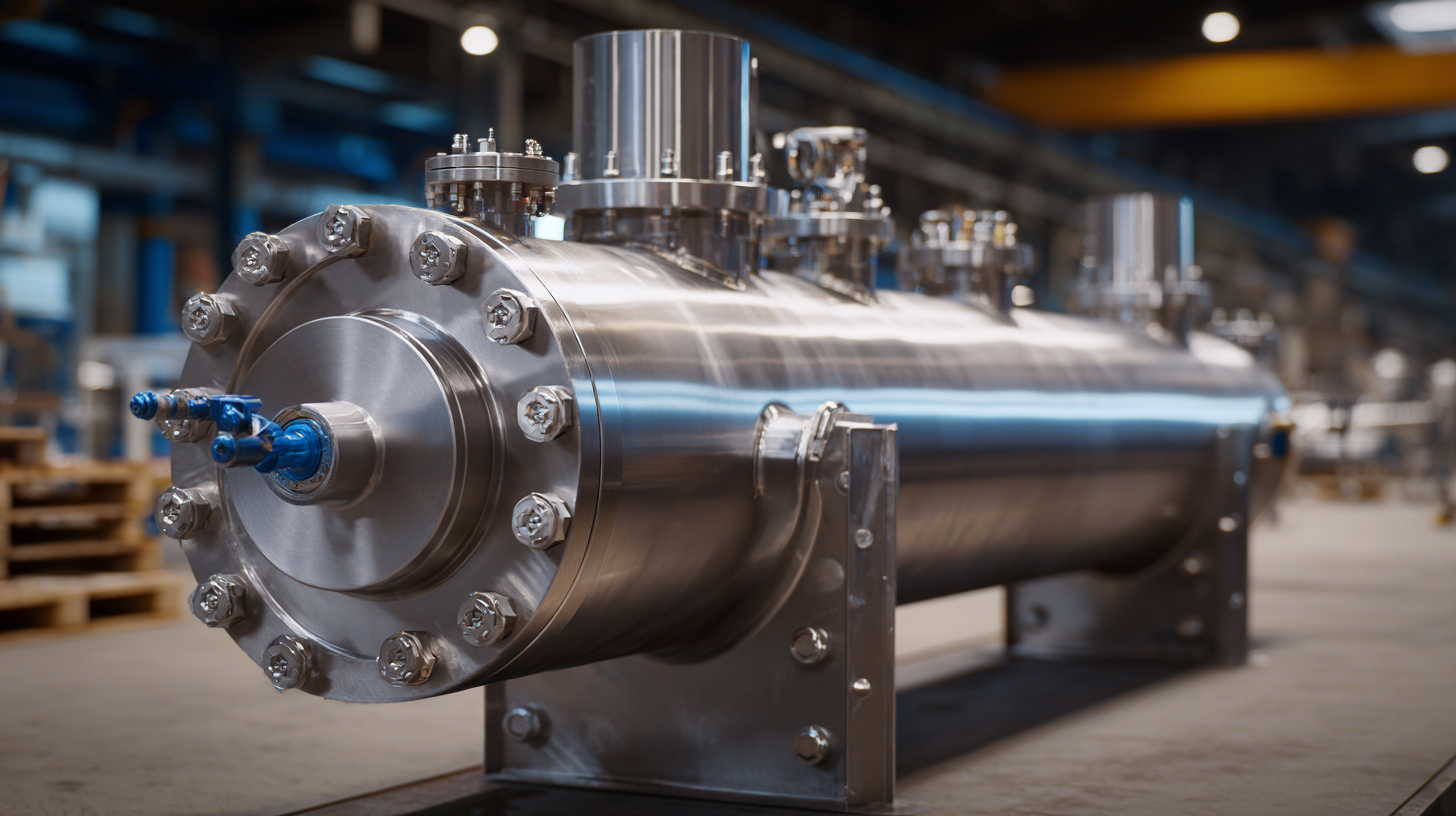

Plate heat exchangers (PHEs) have gained significant traction across various industries due to their efficient thermal performance and compact design. According to a report by Grand View Research, the global plate heat exchanger market is projected to reach USD 8.2 billion by 2025, growing at a CAGR of 8.4%. This surge is primarily driven by the increasing demand for energy-efficient systems, particularly in sectors such as food and beverage, HVAC, and chemical processing. For instance, in the food industry, PHEs are employed for pasteurization processes, enabling substantial energy savings and improved thermal management compared to traditional shell-and-tube systems.

Plate heat exchangers (PHEs) have gained significant traction across various industries due to their efficient thermal performance and compact design. According to a report by Grand View Research, the global plate heat exchanger market is projected to reach USD 8.2 billion by 2025, growing at a CAGR of 8.4%. This surge is primarily driven by the increasing demand for energy-efficient systems, particularly in sectors such as food and beverage, HVAC, and chemical processing. For instance, in the food industry, PHEs are employed for pasteurization processes, enabling substantial energy savings and improved thermal management compared to traditional shell-and-tube systems.

To assess the advantages of PHEs, it's essential to consider their enhanced heat transfer rates and lower maintenance requirements. A study published by ResearchGate highlights that PHEs can achieve up to 20% higher efficiency in thermal transfer compared to conventional heat exchangers. Furthermore, their modular design allows for easier cleaning and servicing, making them ideal for industries that require stringent hygienic standards, such as pharmaceuticals. By integrating PHE technology, businesses can significantly reduce operational costs while adhering to environmental sustainability goals—a critical aspect as industries aim to minimize their carbon footprint amidst growing regulatory pressures.

When selecting the right plate heat exchanger (PHE) for specific applications, several key factors must be considered to ensure optimal performance and efficiency. Firstly, it’s crucial to assess the thermal requirements of the process. This includes understanding the temperature ranges, heat transfer coefficients, and the overall heat load. Each application may require a different design or material, depending on whether the fluid is corrosive, viscous, or subject to fouling.

Another important consideration is the flow arrangement—whether it will be counterflow, parallel flow, or crossflow. Counterflow arrangements often provide greater heat transfer efficiency, making them suitable for applications with significant temperature differences between the hot and cold fluids. Additionally, the PHE's capacity, size, and pressure drop should also be evaluated, as these factors affect operational costs and energy consumption. By carefully analyzing these parameters, industries can ensure they choose the most appropriate PHE, resulting in enhanced performance and reduced long-term operational expenses.

Heat exchangers play a crucial role in various industries, making their maintenance and troubleshooting essential for ensuring optimal performance. Common issues can often arise due to factors such as corrosion, fouling, and improper installation. Regularly inspecting heat exchanger components for signs of wear or degradation can prevent more serious malfunctions. It is vital to implement a schedule for routine maintenance, which may include cleaning, checking for leaks, and ensuring proper fluid flow.

When troubleshooting heat exchangers, a systematic approach is necessary. First, identify the symptoms of the problem, such as unusual temperature fluctuations or pressure drops. This can indicate issues like blockage or inadequate flow rates. Utilizing diagnostic tools and software can aid in pinpointing exact problems, allowing for focused repairs. In case of persistent issues, consulting with experienced engineers or technicians is advisable to leverage their expertise in diagnosing complex scenarios effectively. By prioritizing maintenance and adopting proactive troubleshooting measures, industries can enhance the efficiency and longevity of their heat exchangers, ultimately impacting overall operational success.