Leave Your Message

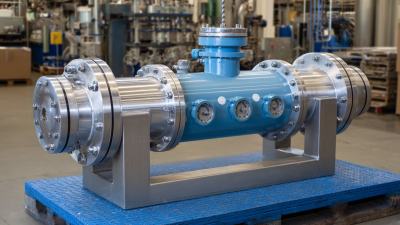

Heat exchanger maintenance is a critical component of operational efficiency in various industries, including oil and gas, power generation, and chemical processing. According to a recent report by the International Energy Agency, improper maintenance can lead to significant inefficiencies, with potential energy losses exceeding 20% in poorly maintained systems. Furthermore, the U.S. Department of Energy estimates that up to 30% of industrial energy consumption is attributed to heating and cooling processes reliant on these pivotal systems. Given these alarming statistics, it is essential for organizations to implement effective maintenance practices to enhance reliability, reduce operational costs, and prevent unscheduled downtimes. This guide will explore actionable strategies for optimizing heat exchanger maintenance, ensuring optimal performance and longevity of these essential components in energy-intensive operations.

Heat exchanger maintenance is a critical component of operational efficiency in various industries, including oil and gas, power generation, and chemical processing. According to a recent report by the International Energy Agency, improper maintenance can lead to significant inefficiencies, with potential energy losses exceeding 20% in poorly maintained systems. Furthermore, the U.S. Department of Energy estimates that up to 30% of industrial energy consumption is attributed to heating and cooling processes reliant on these pivotal systems. Given these alarming statistics, it is essential for organizations to implement effective maintenance practices to enhance reliability, reduce operational costs, and prevent unscheduled downtimes. This guide will explore actionable strategies for optimizing heat exchanger maintenance, ensuring optimal performance and longevity of these essential components in energy-intensive operations.

Understanding heat exchanger efficiency metrics is critical for enhancing maintenance practices. Heat exchangers are pivotal in various industries, from power generation to chemical processing, and their efficiency can significantly impact overall operational performance. According to a report by the Heat Exchange Institute, inefficient heat exchangers can lead to energy losses of up to 25%, underscoring the need for regular performance assessments and maintenance.

Key efficiency metrics, such as the Overall Heat Transfer Coefficient (U-value) and the Temperature Approach, provide insights into the operational efficiency of heat exchangers. By regularly monitoring these metrics, maintenance teams can identify performance deviations early, allowing for timely interventions. For instance, a study presented by the American Society of Mechanical Engineers highlighted that optimizing the U-value through targeted maintenance interventions can improve heat exchanger efficiency by up to 15%, translating to significant cost savings and reduced energy consumption.

Furthermore, integrating technology such as predictive analytics can enhance the understanding of these efficiency metrics. Leveraging tools that analyze temperature differences and flow rates can help predict potential failures and determine the best maintenance schedules, ensuring heat exchangers operate at peak efficiency. As industry standards evolve, businesses that prioritize these efficiency metrics will likely see improved maintenance outcomes and operational reliability.

In the realm of heat exchanger maintenance, monitoring key performance indicators (KPIs) is essential for optimizing efficiency and prolonging equipment lifespan. According to a study conducted by the American Society of Mechanical Engineers, over 30% of energy losses in industrial systems can be traced back to inefficient heat exchanger operation. By regularly assessing parameters such as temperature differentials, pressure drops, and flow rates, facilities can identify early signs of failure and implement corrective actions before they escalate.

Tip: Implement a routine monitoring schedule to assess temperature differentials. A consistent 10-15% increase in temperature difference can signal fouling or reduced heat transfer efficiency, enabling preventative maintenance protocols.

Additionally, pressure drop across the heat exchanger is another crucial KPI. A significant deviation from baseline pressure levels can indicate complications like fouling or scaling. Regularly measuring this will not only enhance thermal performance but also reduce operational costs.

Tip: Utilize advanced diagnostic tools to gauge pressure drop accurately. Investing in smart sensors can facilitate real-time monitoring, allowing for immediate alerts to anomalies that could compromise system integrity.

Regular maintenance of heat exchangers is crucial for maximizing their performance and lifespan. Scheduling maintenance is not just a matter of following a preset timeline; it requires a strategic approach that takes into account the operational demands and environmental conditions of the equipment. It is essential to create a maintenance calendar that aligns with peak usage periods to minimize disruptions. By identifying the best times for routine checks and cleaning, organizations can optimize operational efficiency and prevent unscheduled downtimes.

Incorporating predictive and preventive maintenance practices can further enhance the reliability of heat exchangers. Utilizing data analytics and monitoring systems enables maintenance teams to anticipate potential issues before they become major problems.

Regular performance assessments should be conducted to track efficiency metrics and identify any anomalies that may indicate wear or fouling. By employing a systematic approach to maintenance scheduling, companies can ensure that their heat exchangers not only perform at their best but also achieve a longer operational life, ultimately leading to significant cost savings.

Advanced monitoring technologies have revolutionized the maintenance practices of heat exchangers, facilitating more efficient and effective operations. Traditional maintenance often relies on scheduled inspections and manual checks, which can lead to unforeseen failures and costly downtime. However, by incorporating technologies such as sensors, IoT devices, and predictive analytics, operators can continuously monitor the condition and performance of heat exchangers in real-time. These technologies provide valuable data on temperature, pressure, and flow rates, allowing for immediate identification of anomalies that may indicate malfunction or inefficiency.

Moreover, the integration of machine learning algorithms enhances the ability to predict potential failures before they occur. By analyzing historical performance data, these systems can recognize patterns and provide alerts for necessary maintenance before a problem escalates. This proactive approach not only minimizes unexpected breakdowns but also extends the lifespan of heat exchangers and maximizes their operational efficiency. As industries increasingly adopt these advanced monitoring technologies, the overall reliability of heat exchanger systems is significantly improved, leading to enhanced productivity and reduced operational costs.

When considering heat exchanger maintenance strategies, a cost-benefit analysis of proactive versus reactive approaches can reveal significant insights. Proactive maintenance involves scheduled inspections and timely interventions that prevent system failures before they occur. This approach not only reduces downtime but also extends the lifespan of the heat exchangers, ultimately yielding savings on replacement costs. In contrast, reactive maintenance, which addresses issues post-failure, might seem less expensive in the short term but can lead to substantial operational interruptions and higher repair costs.

To decide which strategy suits your operations best, consider these tips: first, identify critical points in your heat exchanger systems that are prone to failure and prioritize them for proactive care. Next, invest in monitoring technologies that can predict potential breakdowns, allowing for maintenance to be performed only when necessary yet affordably efficient. Finally, establish a detailed maintenance log to track the history of repairs and inspections, which helps in analyzing cost-effectiveness over time, making your maintenance strategy more aligned with your operational goals.