Leave Your Message

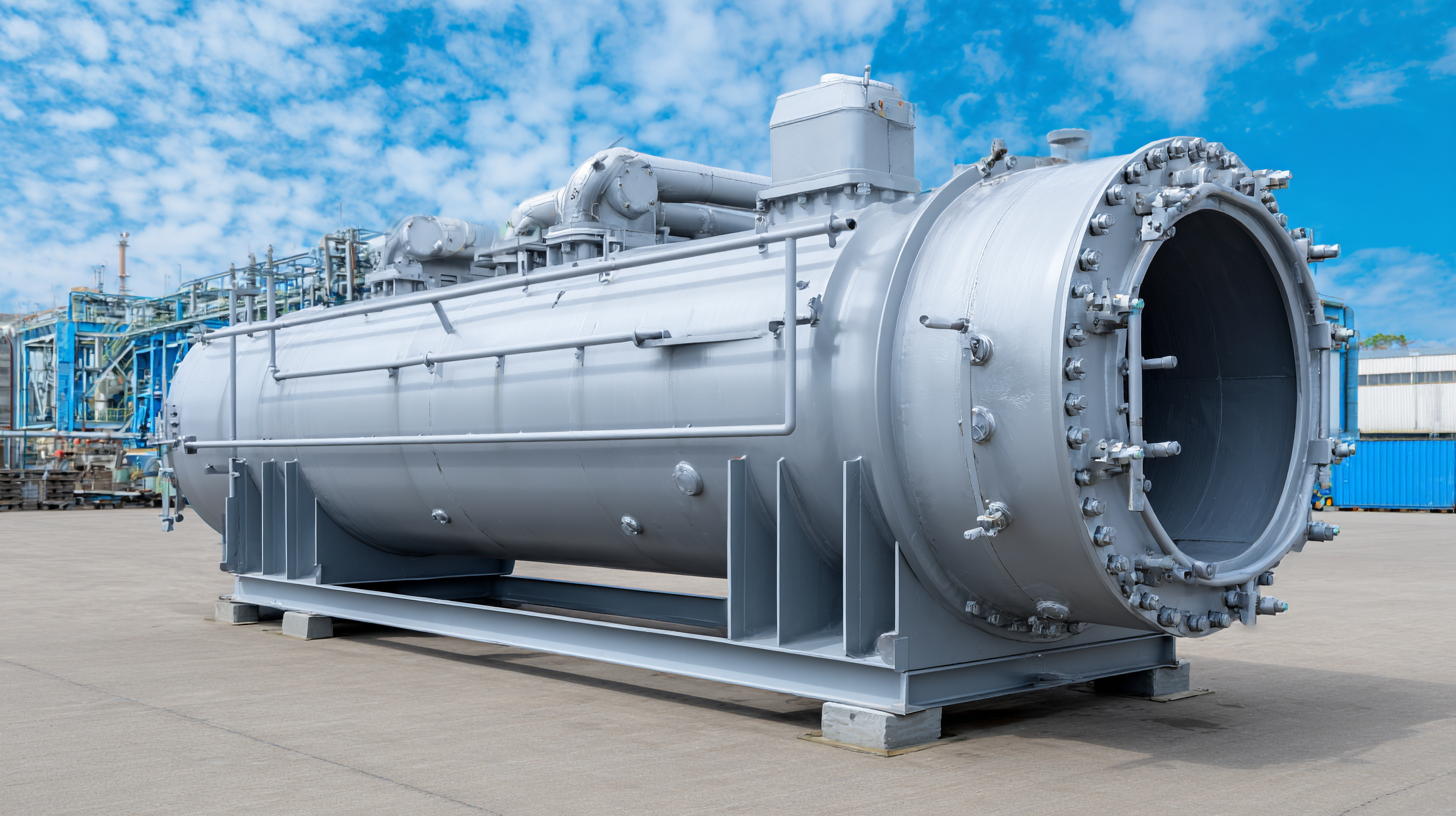

In the quest for sustainable energy solutions, the role of the Industrial Heat Exchanger has emerged as a significant focal point within various industries. As businesses strive to enhance their operational efficiency and reduce energy costs, these sophisticated devices stand out for their ability to recover and recycle waste heat, ultimately improving overall energy efficiency by an impressive 30 percent. This transformative technology not only minimizes energy consumption but also contributes to reducing greenhouse gas emissions, positioning industries as responsible stewards of the environment.

The significance of Industrial Heat Exchangers extends beyond mere energy savings; they epitomize the fusion of innovation and sustainability. In sectors such as manufacturing, chemical processing, and HVAC, these exchangers facilitate heat transfer between fluids, optimizing processes and conserving energy resources. As we delve into the mechanics and advantages of Industrial Heat Exchangers, it becomes clear that their implementation is not merely a trend but a strategic necessity for companies aiming to thrive in an increasingly eco-conscious market.

As we look ahead towards the advancements anticipated by 2025, embracing the capabilities of Industrial Heat Exchangers will be crucial. Their integration within industrial systems will not only help businesses meet regulatory requirements but also provide a competitive edge in a world where efficiency and environmental responsibility are paramount.

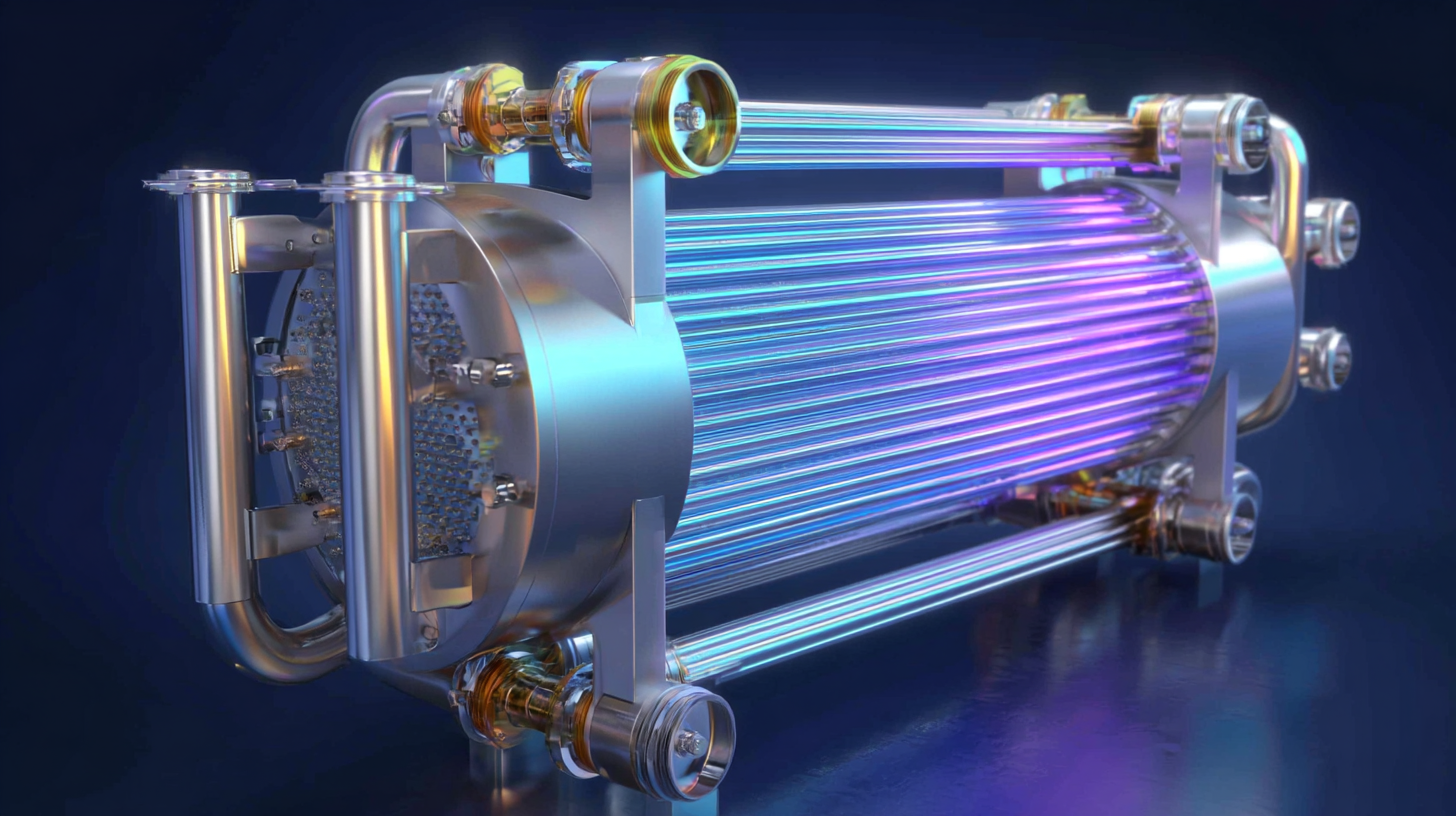

Industrial heat exchangers are essential components in various industrial processes, designed to transfer heat between two or more fluids without them coming into direct contact. Their primary function is to enhance thermal efficiency by utilizing waste heat from equipment or processes, thus optimizing energy usage. By doing so, these systems can significantly reduce the amount of energy required for heating or cooling operations, leading to improved overall efficiency.

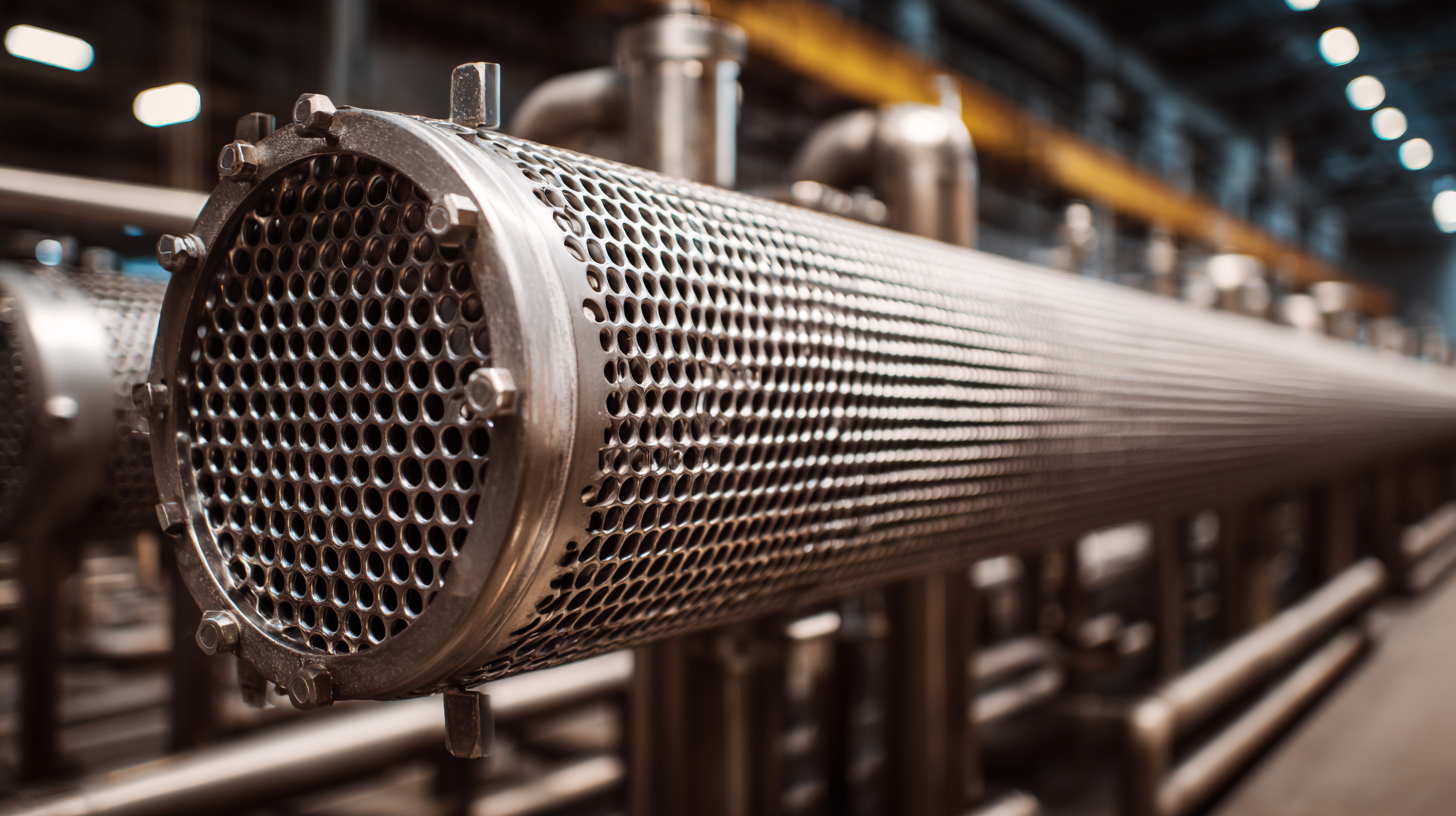

Understanding the basic types of heat exchangers, such as shell and tube, plate, and air-cooled exchangers, is crucial for industries aiming to maximize their energy efficiency. Each type has unique characteristics suited for different applications. For example, shell and tube exchangers are often used in high-pressure applications, while plate exchangers offer high surface area and efficiency in compact designs. By implementing these devices effectively, industries can realize energy savings of up to 30 percent, contributing not only to reduced operational costs but also to environmental sustainability efforts by minimizing energy consumption and greenhouse gas emissions.

| Dimension | Value | Description |

|---|---|---|

| Heat Exchanger Type | Shell and Tube | Common type for industrial applications |

| Material | Carbon Steel | Durable and cost-effective material |

| Operating Temperature | 150°C | Typical temperature for industrial processes |

| Efficiency Gain | 30% | Improvement in energy efficiency |

| Fluid Types | Water and Oil | Common fluids used in heat exchange |

| Maintenance Frequency | Annual | Recommended maintenance schedule |

| Applications | Chemical Processing, HVAC | Industries where heat exchangers are essential |

Energy efficiency has emerged as a critical focal point in industrial applications, especially in the face of rising energy costs and environmental concerns. As industries strive to lower operational costs and minimize their carbon footprint, enhancing energy efficiency is no longer optional but essential. For instance, the growing interest in advanced technologies, such as industrial heat exchangers, highlights the industry's commitment to achieving significant energy savings. These innovations can lead to improvements in energy efficiency by as much as 30 percent, making them integral to modern industrial operations.

Furthermore, the importance of energy efficiency is underscored by initiatives like the Energy Efficiency Optimization Research Center recently established in Chongqing. This center aims to drive the city’s transition towards a greener, low-carbon future by promoting research and implementation of energy-efficient technologies. Events such as the International Talent Exchange Conference exemplify collaborative efforts to facilitate the transformation of innovative energy solutions into tangible applications, further emphasizing the urgency of prioritizing energy efficiency in industrial setups.

This chart illustrates the percentage of energy efficiency improvements achieved by implementing industrial heat exchangers in various sectors. The data shows a significant average improvement of 30% across different industries.

Heat exchangers play a crucial role in enhancing energy efficiency across various industrial sectors. By facilitating the transfer of thermal energy between two or more fluids, they can significantly reduce operational costs. According to a report by the U.S. Department of Energy, the implementation of efficient heat exchangers can result in energy savings of up to 30%. This is particularly beneficial for industries such as chemical processing, oil and gas, and HVAC, where heat recovery systems can be integrated into existing processes to minimize energy consumption.

The benefits of utilizing heat exchangers extend beyond energy savings. They also contribute to reduced greenhouse gas emissions, improving a company's sustainability profile. The International Energy Agency estimates that enhancing heat recovery systems could potentially cut global energy demand by 9% by 2040. Furthermore, businesses adopting advanced heat exchanger technologies can experience improvements in overall system reliability and longevity, decreasing maintenance costs and unplanned downtime, which offers significant financial advantages in competitive markets.

Industrial heat exchangers are vital components that enhance energy efficiency by facilitating effective heat transfer between different fluids. The key types of industrial heat exchangers include shell and tube, plate, air-cooled, and double pipe exchangers, each designed for specific applications such as aerospace, oil and gas, chemical processing, and automotive industries. These exchangers significantly contribute to increasing operational efficiency, targeting energy savings of up to 30 percent, which is crucial in today’s energy-conscious environment.

Industrial heat exchangers are vital components that enhance energy efficiency by facilitating effective heat transfer between different fluids. The key types of industrial heat exchangers include shell and tube, plate, air-cooled, and double pipe exchangers, each designed for specific applications such as aerospace, oil and gas, chemical processing, and automotive industries. These exchangers significantly contribute to increasing operational efficiency, targeting energy savings of up to 30 percent, which is crucial in today’s energy-conscious environment.

According to market research, the global nickel alloy market is on an upward trajectory, projected to grow from USD 5.87 billion in 2026 to USD 7.02 billion by 2035, reflecting a stable compound annual growth rate (CAGR) of 2%. This growth is driven by the increasing use of nickel alloys in high-performance applications, particularly in industries requiring corrosion resistance and high-temperature performance. As sectors like aerospace and automotive continue to expand, the demand for specialized materials such as nickel-based alloys will remain strong.

Tip: When considering energy-efficient solutions in industrial processes, invest in modern heat exchanger technologies that not only improve performance but also yield significant long-term cost savings. Furthermore, staying informed about market trends in materials such as nickel alloys can provide a competitive edge in manufacturing and engineering applications.

Maximizing efficiency in heat exchanger systems requires a multifaceted approach that incorporates careful design, regular maintenance, and advanced technologies. One of the primary strategies is to select the appropriate type of heat exchanger based on the specific application and fluid properties. For instance, finned tube exchangers can enhance heat transfer in scenarios where space is limited, while counterflow designs often provide superior efficiency compared to parallel flow arrangements. By customizing equipment to fit operational demands, industries can significantly optimize thermal performance.

Another key strategy for enhancing efficiency is the implementation of automation and control systems that monitor heat transfer performance in real-time. By utilizing sensors and smart controls, facilities can adjust parameters dynamically to respond to fluctuating process conditions, ensuring optimal operation. Additionally, regular maintenance, such as cleaning and inspection, is critical for preventing fouling and other issues that can diminish heat exchanger efficiency. Investing in advanced materials and coatings can also help to reduce corrosion and enhance durability, leading to improved performance and reduced downtime.