Leave Your Message

In today’s competitive manufacturing landscape, energy efficiency has emerged as a crucial component for sustainable operations. Central to achieving this efficiency is the use of Industrial Heat Exchangers, which play a pivotal role in optimizing energy use within various production processes. These innovative devices allow for the transfer of heat from one fluid to another, significantly reducing wasted energy and lowering operating costs. As industries continue to seek solutions that not only enhance performance but also mitigate environmental impact, understanding the benefits and applications of Industrial Heat Exchangers becomes essential.

This article will explore practical tips and insights into how integrating these systems can lead to substantial improvements in energy efficiency, benefiting both manufacturers and the environment alike.

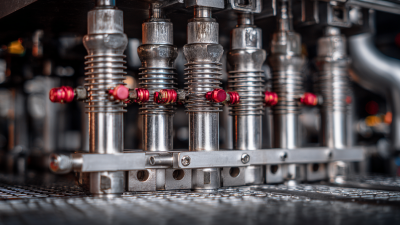

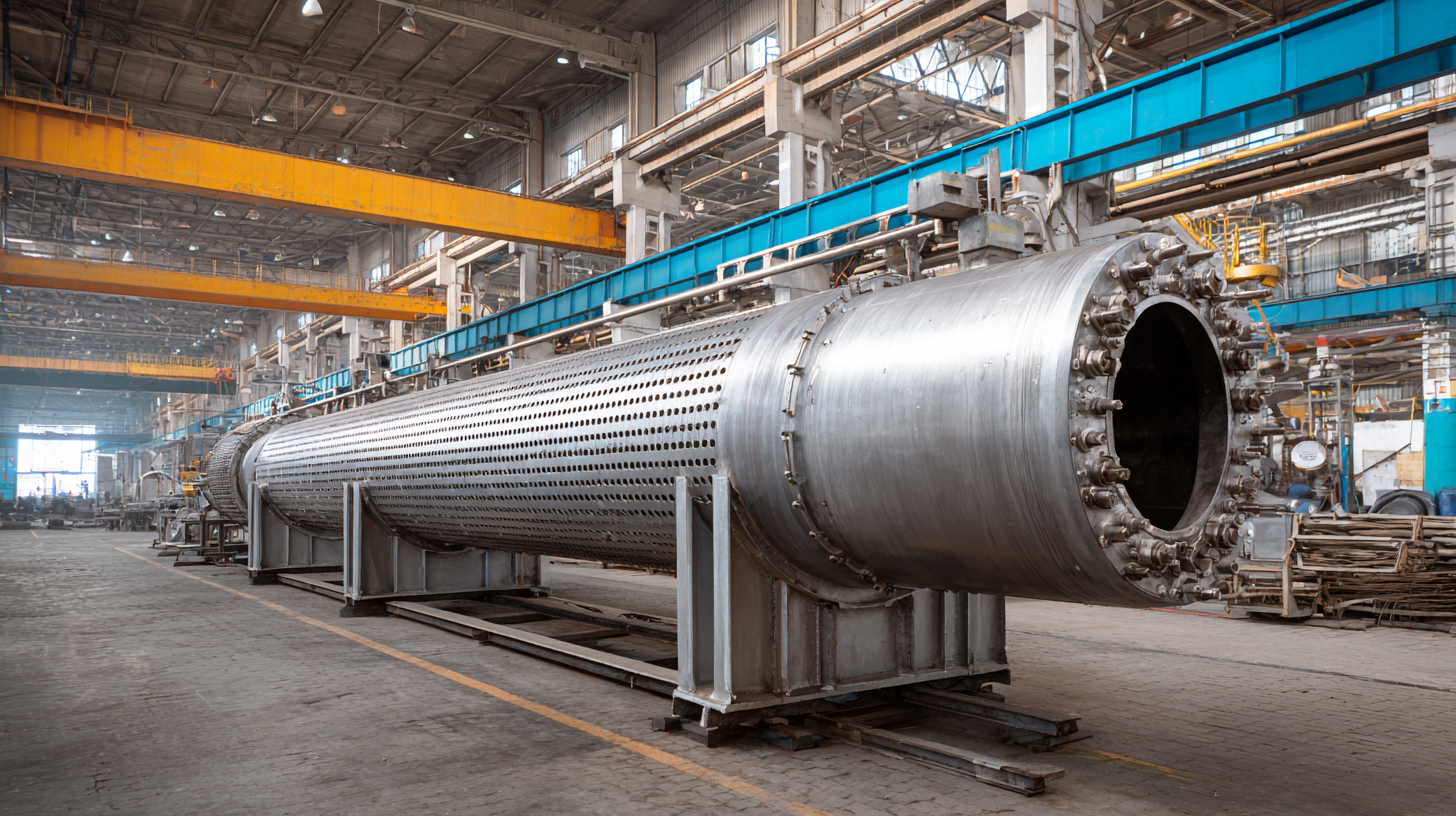

Industrial heat exchangers play a crucial role in enhancing energy efficiency within manufacturing processes. Various types of heat exchangers are utilized, each designed to meet specific operational needs and conditions. One of the most common types is the shell-and-tube heat exchanger, which consists of a series of tubes where one fluid flows through the tubes and another fluid flows around the tubes, allowing for efficient heat transfer. This design is particularly favored for its ability to handle high-pressure systems.

Another significant type is the plate heat exchanger, which features a series of thin plates that provide a large surface area for heat transfer while occupying less space than shell-and-tube models. These are typically used in applications where space constraints exist and allow for easy maintenance and cleaning. Additionally, air-cooled heat exchangers utilize ambient air to cool hot fluids and are increasingly being used in industries that require cooling without the need for water, posing a sustainable alternative in energy-intensive operations. By employing these diverse heat exchanger technologies, manufacturers can optimize energy usage, reduce operational costs, and minimize environmental impact.

Industrial heat exchangers play a crucial role in enhancing energy efficiency within manufacturing processes. According to a report by the U.S. Department of Energy, heat exchangers can improve thermal efficiency by 30% or more, significantly reducing energy consumption in facilities. By capturing waste heat from various manufacturing processes and repurposing it for heating, preheating, or even electricity generation, businesses can minimize their reliance on external energy sources and lower operational costs.

Moreover, heat exchangers contribute to a reduction in greenhouse gas emissions. The International Energy Agency estimates that implementing advanced heat exchanger technologies could potentially decrease CO2 emissions from industrial sectors by about 20%. This transition to more energy-efficient systems not only supports environmental sustainability but also aligns with global initiatives aimed at reducing the carbon footprint. Businesses that invest in high-performance heat exchangers can see returns through decreased energy expenditures while promoting a greener manufacturing environment, making them an essential component in the pursuit of energy efficiency.

When selecting the appropriate type of industrial heat exchanger, several key factors come into play that significantly affect energy efficiency in manufacturing processes. One of the foremost considerations is the specific thermal requirements of the application. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), energy savings can reach up to 30% when utilizing a heat exchanger that is precisely matched to the temperature and flow rate of the process streams.

Another critical factor is the material compatibility with the fluids involved. Corrosive fluids necessitate the use of materials that can withstand chemical reactions, allowing for longer equipment life and reduced downtime for maintenance. The World Energy Council reports that improper selection can lead to a decrease in efficiency by as much as 15%, underscoring the importance of material choice in achieving optimal performance.

Finally, the physical space available for installation and maintenance can limit the options for heat exchanger designs. Compact designs, such as plate heat exchangers, are often favored in environments where space and weight are constraints. Research shows that these designs can improve energy recovery by up to 25%, confirming that selecting the right type of heat exchanger is crucial for ensuring both efficiency and operational viability in manufacturing.

Regular maintenance practices are crucial for ensuring optimal performance of industrial heat exchangers, which play a vital role in enhancing energy efficiency in manufacturing processes. One of the key maintenance activities is routine inspection, which helps identify any potential issues such as leaks or corrosion that could hinder the heat exchanger's effectiveness. Implementing a strict schedule for inspections enables manufacturers to address minor problems before they escalate into significant failures, ultimately saving time and costs related to production downtime.

Cleaning is another essential maintenance practice that cannot be overlooked. Over time, heat exchangers can accumulate fouling deposits, which can significantly reduce their thermal performance. Depending on the type of fluid and the working environment, different cleaning methods, such as chemical cleaning or mechanical cleaning, may be employed. Regular cleaning not only enhances heat transfer efficiency but also prolongs the lifespan of the equipment, ensuring manufacturers can maintain consistent operational output.

Additionally, monitoring the performance of heat exchangers through advanced diagnostic tools can provide valuable insights into their operation. By keeping track of temperature differentials, pressure drops, and flow rates, manufacturers can assess the efficiency of their heat exchangers and optimize their settings accordingly. This proactive approach to maintenance empowers manufacturers to achieve better energy efficiency, reduce operational costs, and promote sustainability in their manufacturing processes.

| Maintenance Practice | Frequency | Benefits | Impact on Energy Efficiency |

|---|---|---|---|

| Visual Inspection | Monthly | Early detection of leaks and corrosion | Prevents energy loss due to fluid leaks |

| Cleaning | Quarterly | Removal of fouling and buildup | Enhances thermal efficiency |

| Fluid Replacement | Annually | Maintains optimal heat transfer properties | Prevents degradation of energy efficiency over time |

| Performance Testing | Bi-Annually | Identifies performance issues early | Supports continuous optimal operation |

| Leak Testing | As needed | Ensures system integrity | Minimizes energy waste |

The future of heat exchanger technology is pivotal for enhancing sustainability in manufacturing. As industries shift towards greener practices, the integration of innovative heat exchanger systems is essential. These advancements not only improve energy efficiency but also minimize waste heat generation. For instance, the rise of low-temperature nitrogen rejection units and the combination of traditional low-temperature technologies with membrane separation techniques promise significant improvements in thermal management across various sectors, including food and beverage, aerospace, and defense.

Moreover, the growing importance of thermal energy recovery systems positions heat exchangers at the forefront of industrial transformation. With predictions indicating substantial market growth for automotive radiators and green data centers in the coming years, the emphasis on sustainable manufacturing continues to intensify. Companies are increasingly investing in smart, energy-efficient heat exchanger designs that leverage renewable energy sources, such as solar thermal and photovoltaic technologies. This not only enhances operational efficiency but also supports global efforts towards achieving carbon neutrality.