Leave Your Message

The quest for sustainable manufacturing practices is driving industries to seek innovative solutions that enhance energy efficiency. One critical component in this transformation is the Industrial Heat Exchanger, which plays a pivotal role in optimizing thermal energy management across various sectors. According to the International Energy Agency (IEA), energy efficiency improvements in industrial processes could collectively lead to a reduction of up to 10% in global energy demand by 2030. Furthermore, a report by MarketsandMarkets estimates the heat exchanger market will grow from USD 15.46 billion in 2020 to USD 25.65 billion by 2026, reflecting an increased emphasis on energy conservation and emissions reduction. By incorporating advanced designs and automation technology, Industrial Heat Exchangers are set to revolutionize the way manufacturers approach energy consumption, paving the way for a more sustainable industrial landscape.

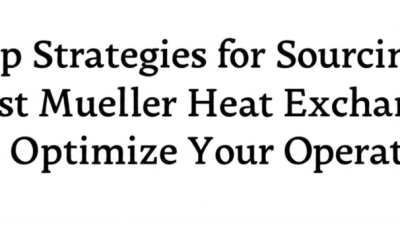

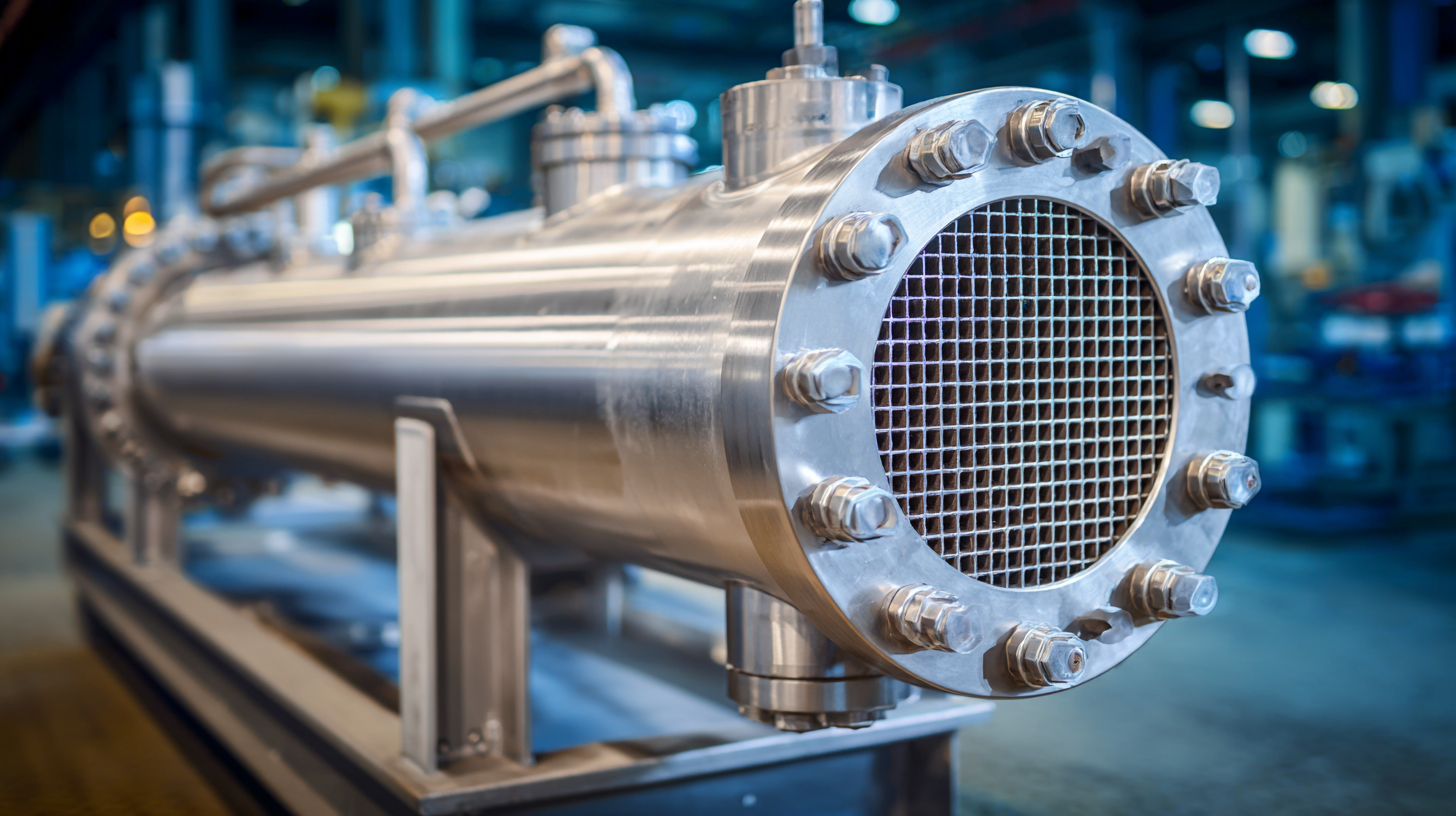

Industrial heat exchangers play a crucial role in enhancing energy efficiency within manufacturing processes. These devices facilitate the transfer of heat between two or more fluids, allowing industries to reclaim and reuse waste heat that would otherwise be lost. By optimizing heat transfer, industrial heat exchangers not only reduce energy consumption but also minimize greenhouse gas emissions, contributing significantly to sustainable manufacturing practices.

Tip: Regular maintenance of heat exchangers is essential for optimal performance. Ensure that your heat exchangers are free from fouling and scale build-up, as this can significantly hinder their efficiency. Conducting routine inspections can help identify potential issues before they escalate, ensuring peak operational performance.

The technology behind industrial heat exchangers is continually evolving, with advancements in materials and design leading to better effectiveness and durability. Applications range from chemical processing to power generation, demonstrating their versatility across various sectors. Incorporating innovative heat exchanger solutions can help manufacturers achieve significant cost savings and bolster sustainability goals.

Tip: When selecting a heat exchanger, consider the specific requirements of your process, including temperature, pressure, and fluid type. By matching the right exchanger to your application, you can enhance energy recovery and improve overall operational efficiency.

In the journey toward sustainable manufacturing, energy efficiency plays a pivotal role. Industries are increasingly recognizing the importance of optimizing energy use not only to cut costs but also to minimize their environmental footprint. By leveraging advanced technologies such as industrial heat exchangers, manufacturers can significantly enhance their energy efficiency, leading to a more sustainable operation. These systems facilitate the recovery and reuse of heat from processes, reducing reliance on external energy sources and lowering greenhouse gas emissions.

**Tips for Enhancing Energy Efficiency:**

1. Regularly maintain and inspect industrial heat exchangers to ensure maximum performance and prevent energy losses.

2. Implement monitoring systems to track energy consumption patterns, helping identify areas for improvement.

Furthermore, the integration of energy-efficient practices empowers manufacturers to comply with increasingly stringent environmental regulations and meet the growing demand for sustainable products. By optimizing energy use, manufacturers can not only boost their productivity but also position themselves as leaders in an eco-conscious market. This shift not only benefits the planet but can also enhance brand reputation and customer loyalty.

Heat exchangers play a crucial role in enhancing energy efficiency within industrial settings, offering multiple advantages that contribute to sustainable manufacturing practices. One of the primary benefits is their ability to recycle waste heat, which can significantly reduce energy consumption. By transferring thermal energy from one medium to another, heat exchangers enable industries to recover heat that would otherwise be lost, allowing this energy to be repurposed for other processes or used to heat water. This not only lowers overall energy costs but also decreases greenhouse gas emissions, aligning with sustainability goals.

In addition to energy conservation, heat exchangers contribute to improved process efficiency. Systems equipped with these devices can maintain optimal operating temperatures, enhancing product quality and consistency. Advanced designs, such as plate and shell heat exchangers, offer flexibility and can be customized for specific industrial processes, leading to minimized downtime and increased productivity. The integration of heat exchangers also supports regulatory compliance by helping companies meet environmental standards, making them a pivotal component in the shift toward greener manufacturing practices.

The adoption of industrial heat exchangers for energy optimization presents a myriad of challenges that must be addressed to revolutionize energy efficiency in sustainable manufacturing. Recent projections indicate that the global heat exchanger market is set to reach USD 43.37 billion by 2033, with a compound annual growth rate (CAGR) of 7.23% from 2025 to 2033. This growth underscores the increasing importance of heat exchangers in a landscape where energy efficiency and sustainability are paramount for industry players. However, the integration of such technologies often meets hurdles, such as the significant capital costs, technical complexities, and the need for skilled personnel to maintain advanced systems.

Moreover, as industries expand their energy systems, the need for innovative solutions in thermal energy storage becomes clearer. Enhanced mechanisms in waste heat recovery, projected to reach a market value of USD 142.9 billion by 2034 with a CAGR of 7.6%, highlight the potential for heat exchangers to play a vital role in large-scale energy optimization. These emerging trends indicate that while the path toward incorporating heat exchangers in manufacturing is fraught with challenges, the opportunity for substantial energy savings and sustainability improvements is significant, driving the need for continued investment and innovation in the sector.

The future of heat exchanger technology is poised for significant advancements that will enhance energy sustainability across various industries. As manufacturers increasingly prioritize energy efficiency, innovations such as enhanced surface designs, compact heat exchanger systems, and advanced materials are emerging. These developments not only improve thermal performance but also reduce the footprint of heat exchangers, making them suitable for a wider range of applications, from chemical processing to power generation.

The future of heat exchanger technology is poised for significant advancements that will enhance energy sustainability across various industries. As manufacturers increasingly prioritize energy efficiency, innovations such as enhanced surface designs, compact heat exchanger systems, and advanced materials are emerging. These developments not only improve thermal performance but also reduce the footprint of heat exchangers, making them suitable for a wider range of applications, from chemical processing to power generation.

Moreover, the integration of smart technologies and Internet of Things (IoT) capabilities into heat exchangers promises to optimize performance further. By utilizing real-time data and predictive analytics, industries can monitor system efficiency and anticipate maintenance needs, thereby minimizing downtime and energy waste. These trends signal a shift towards a more sustainable approach in manufacturing, where heat exchangers play a crucial role in achieving lower carbon emissions and enhancing overall operational efficiency. As such, the evolution of heat exchanger technology is not just a technical upgrade; it is a vital component in the quest for a greener, more sustainable industrial landscape.