Leave Your Message

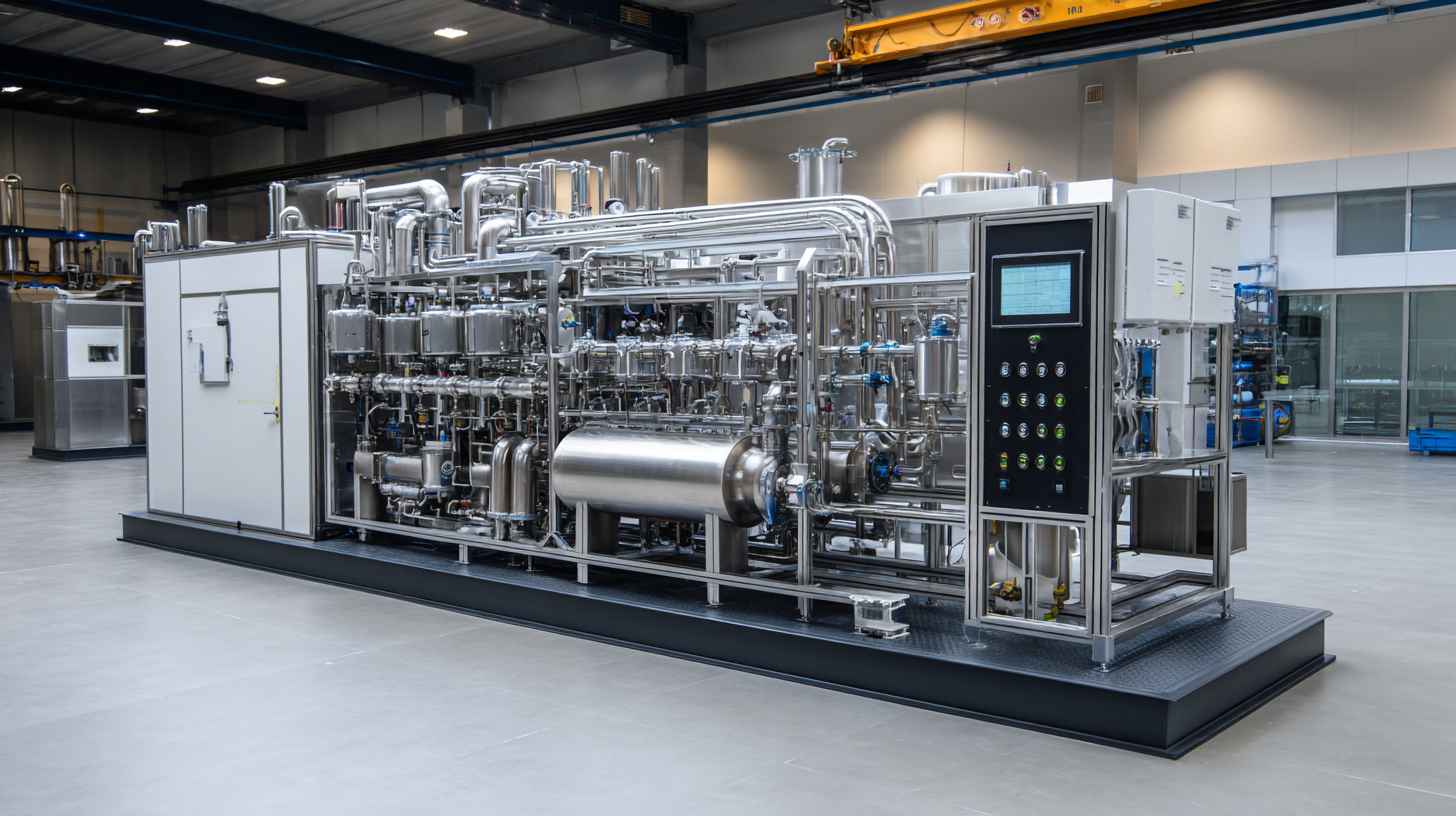

In the dynamic landscape of food processing, the role of Food Heat Exchangers is pivotal in enhancing operational efficiency and product quality. According to a recent industry report by Research and Markets, the global food heat exchangers market is projected to reach $2.3 billion by 2026, demonstrating a CAGR of 5.2% during the forecast period. This growth is driven by increasing demand for energy-efficient solutions and stringent food safety regulations that compel manufacturers to invest in advanced heat exchange technologies. Food heat exchangers play critical roles across various applications, including dairy processing, beverage production, and meat processing, where they facilitate optimal thermal management. Understanding the intricacies of these systems not only allows manufacturers to improve productivity but also helps in maintaining the integrity and freshness of the food products. In this ultimate guide, we will explore the essential aspects of food heat exchangers, supported by industry case studies, to assist you in making informed decisions for your processing needs.

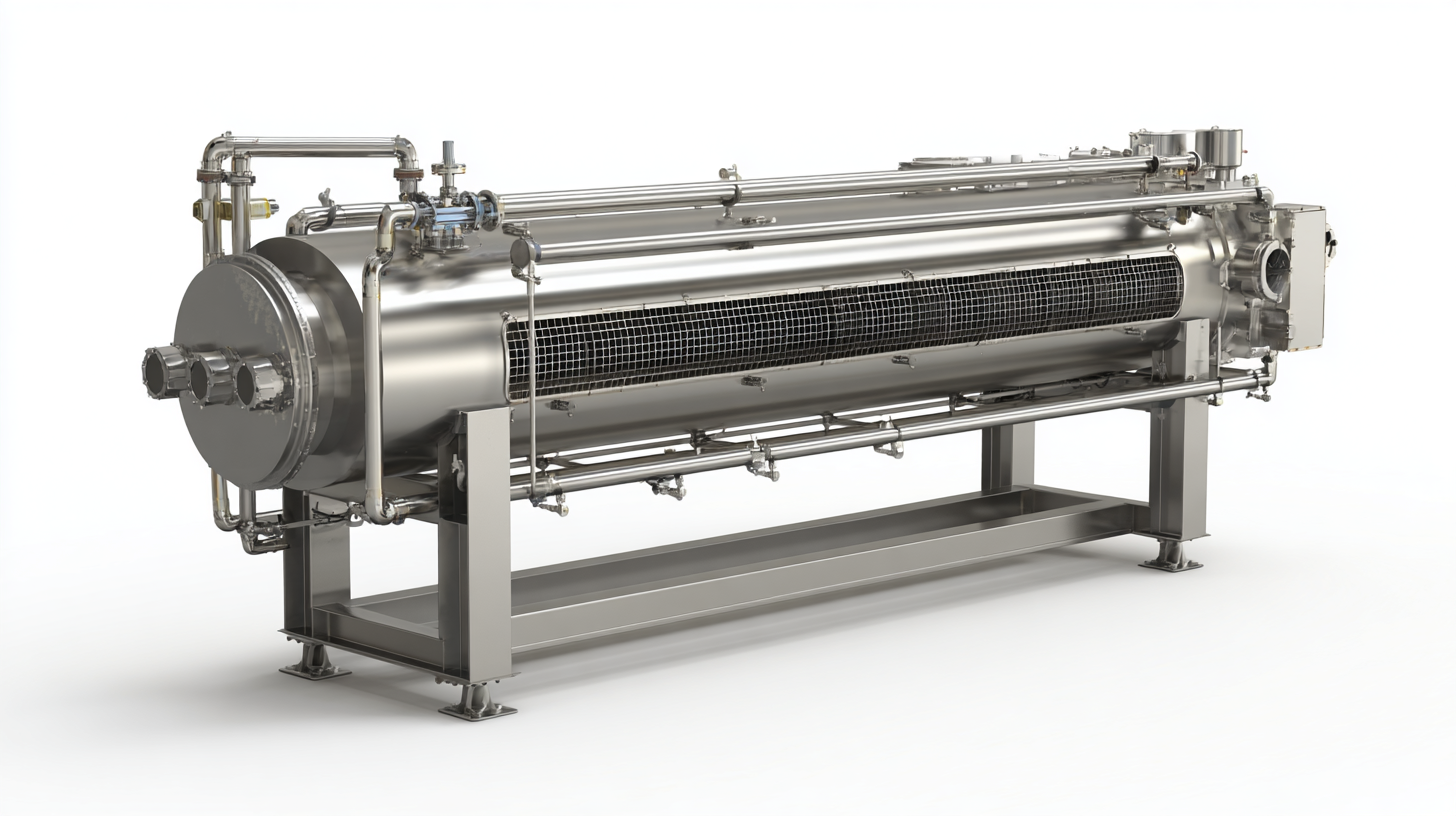

Heat exchangers are vital in the food processing industry, ensuring that temperature control is achieved efficiently. Understanding their key components—such as the heat transfer surface, flow arrangement, and insulation—is essential for optimal performance. The most common types of heat exchangers used in food processing include shell-and-tube, plate, and air-cooled exchangers. Each type serves a unique purpose, so selecting the right one can greatly impact energy efficiency and product quality.

When choosing a heat exchanger, it's crucial to consider factors such as the type of food product, processing temperature, and volume. Ensure that the materials used are compatible with the food products to avoid contamination. Additionally, evaluate the maintenance requirements to support long-term efficiency.

**Tip:** Regularly inspect and clean your heat exchangers to prevent fouling, which can significantly reduce performance.

Also, think about energy recovery systems that can utilize waste heat to preheat incoming products, leading to reduced energy costs and enhanced sustainability in your operations.

**Tip:** Investing in energy-efficient models may have a higher initial cost but can result in substantial savings over time.

When it comes to food processing, the efficiency of heat exchangers is paramount for ensuring optimal thermal performance. To evaluate the efficiency of these systems, it is essential to measure key parameters such as heat transfer coefficient, temperature difference, and flow rates. A comprehensive understanding of these metrics allows operators to optimize their processes, ultimately leading to enhanced product quality and reduced energy consumption.

One effective method for measuring heat transfer performance is the use of the Log Mean Temperature Difference (LMTD) approach, which provides insights into the thermal gradients across the heat exchanger. This technique can be combined with the overall heat transfer coefficient to calculate the heat transfer rate more precisely. Additionally, employing techniques like temperature profiling and flow visualization can help identify potential inefficiencies, such as dead zones or unexpected thermal losses, enabling operators to make informed adjustments to their systems.

Regular monitoring and analysis of these performance indicators not only improve the efficiency of food heat exchangers but also contribute to compliance with safety and quality standards. By prioritizing efficiency evaluation techniques, food processors can ensure their operations remain competitive in an ever-evolving industry while maintaining the highest levels of quality and sustainability.

When it comes to ensuring food safety in your kitchen, the material of your cookware is paramount. Stainless steel is often hailed as one of the best options for food processing due to its non-reactive qualities and resistance to corrosion. Unlike some alternatives, stainless steel does not leach harmful chemicals into food, making it a safe choice for cooking. Additionally, it provides excellent durability, which can stand up to high temperatures and frequent usage.

Tips for selecting the right stainless steel cookware include looking for options with a high nickel content, as this encourages better durability and corrosion resistance. It’s also wise to choose products that are labeled as food-grade stainless steel to ensure they meet safety standards. When considering other materials, such as non-stick coatings, be aware of potential toxic substances that may be harmful over time. Opting for ceramic or glass can be a great alternative, but check for certifications that confirm their safety and efficacy.

Moreover, the manufacturing process and the brand's commitment to food safety are just as important as the material itself. Researching cooking tools that are free of harmful substances like PFAS and BPA can greatly enhance your kitchen's safety profile. Keeping these considerations in mind will help you make informed choices for a healthier cooking experience.

When selecting heat exchangers for different food products, it's essential to consider the specific needs of each application. Food safety and authenticity are paramount, and recent advancements like ion mobility spectrometry (IMS) can enhance monitoring during processing. Understanding the thermal properties and interactions of various food products allows for more efficient heat exchanger selection and design, ultimately impacting product quality and safety.

Tips for Choosing the Right Heat Exchanger:

By understanding these factors and leveraging modern technologies, stakeholders can make informed decisions that enhance both processing efficiency and the sustainability of food production.

Maintaining food heat exchangers is essential for ensuring their longevity and optimal performance in processing applications. Regular maintenance can significantly impact efficiency; according to a report by the Food Processing Technology Institute, poorly maintained heat exchangers can lead to a 20-30% drop in thermal efficiency. This emphasizes the importance of developing a comprehensive maintenance schedule that includes routine inspections and cleaning to prevent fouling and scaling, which are common issues that can impair heat transfer.

Additionally, it is crucial to monitor the operating conditions of heat exchangers. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends that operators maintain specific temperature differentials to avoid thermal shock and material degradation. Implementing predictive maintenance techniques, guided by data analytics, allows for early identification of potential failures. Studies show that companies using predictive maintenance can reduce downtime by up to 50%, thus enhancing productivity in food processing operations. By prioritizing these maintenance tips, businesses can ensure the reliability and efficiency of their food heat exchangers, safeguarding their investment in processing technology.

| Heat Exchanger Type | Efficiency (%) | Maintenance Frequency (Months) | Common Applications | Material |

|---|---|---|---|---|

| Plate Heat Exchanger | 80-90 | 6 | Dairy Pasteurization | Stainless Steel |

| Shell and Tube | 75-85 | 12 | Juice Pasteurization | Carbon Steel |

| Air Cooled Heat Exchanger | 70-80 | 9 | Cooling Process | Aluminum |

| Double Tube Heat Exchanger | 65-75 | 8 | Food Processing | Copper |

| Brazed Plate Heat Exchanger | 85-95 | 3 | Beer Brewing | Nickel-Brazed Steel |