01

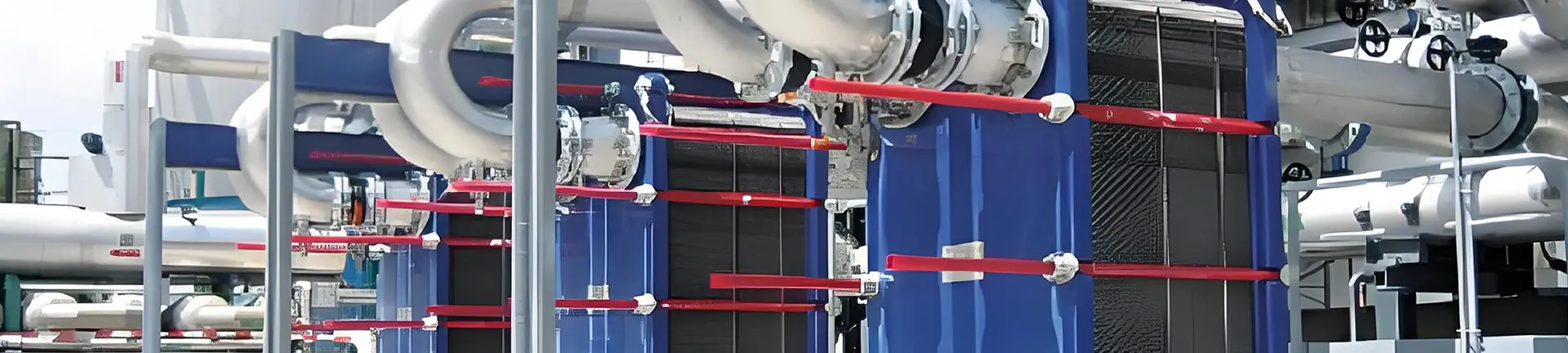

Welded Plate Compact Heat Exchanger

Key Features of Welded Plate Compact Heat Exchangers

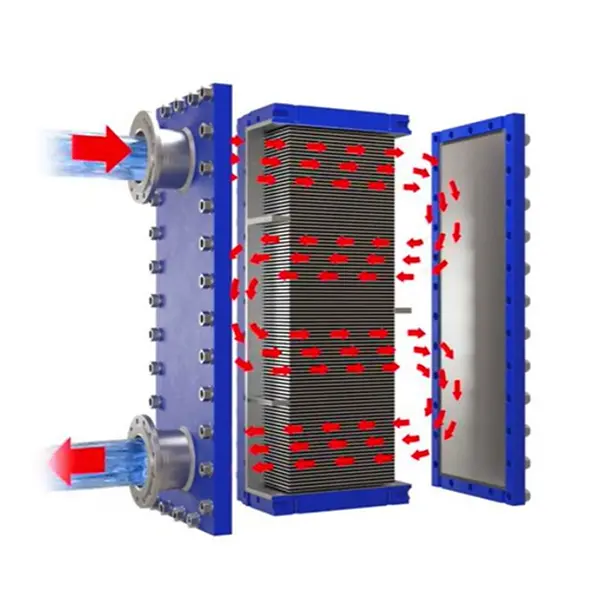

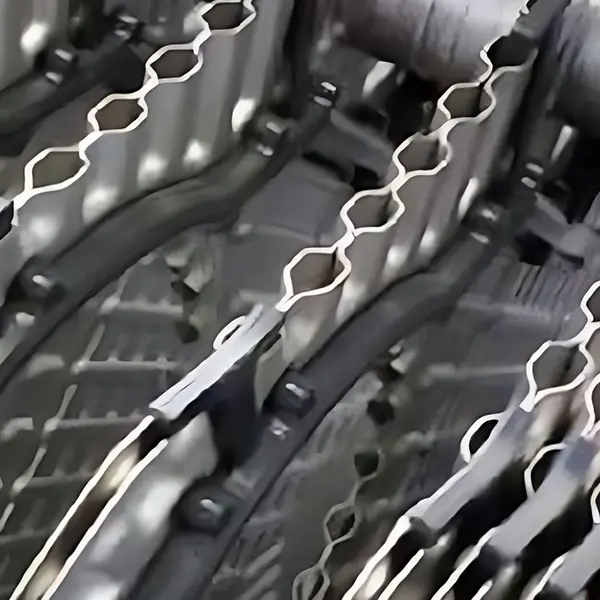

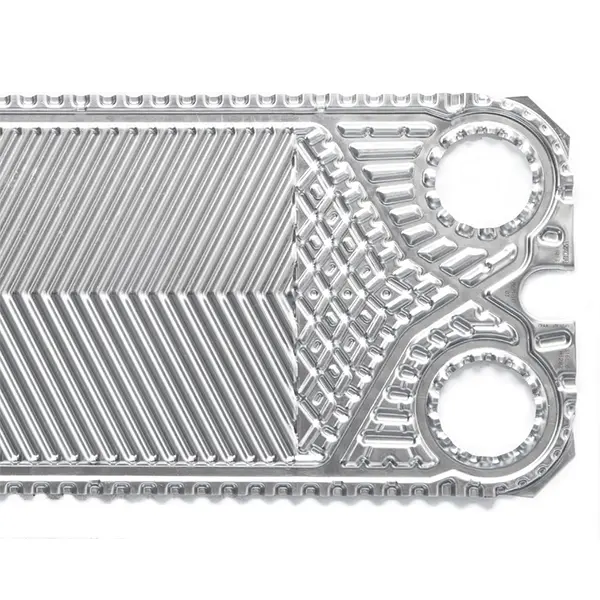

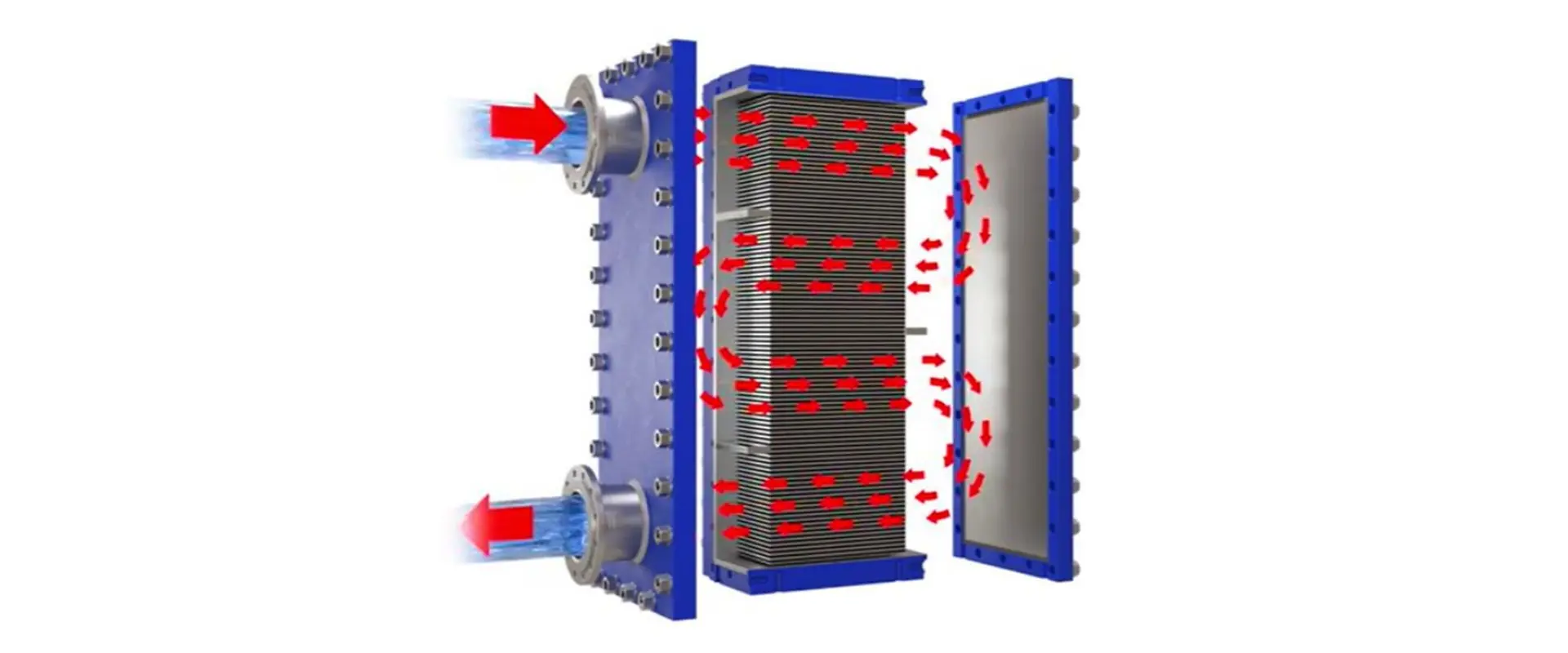

1. High Heat Transfer Efficiency:

The corrugated design of the plates increases the surface area and promotes turbulent flow, which enhances heat transfer efficiency. The heat transfer coefficient can reach 6000-8000 W/m²·°C, significantly higher than traditional heat exchangers.

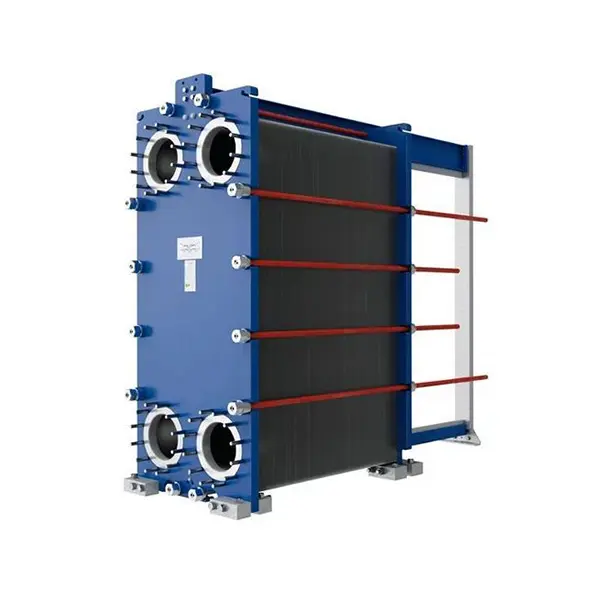

2. Compact Design:

WPCHEs have a high ratio of heat transfer area to volume, making them much more compact than shell-and-tube heat exchangers. This compact design reduces the space required for installation and operation.

3. High Temperature and Pressure Resistance:

WPCHEs can operate at high temperatures (up to 400°C) and pressures (up to 3.5 MPa), making them suitable for demanding industrial applications.

4. No Gasket Seals:

The fully welded structure eliminates the need for gaskets, reducing the risk of leaks and maintenance issues associated with gasket degradation.

5. Low Fouling Tendency:

The design of the plates and the turbulent flow of the fluid reduce the likelihood of fouling, which can significantly extend the service life of the heat exchanger.

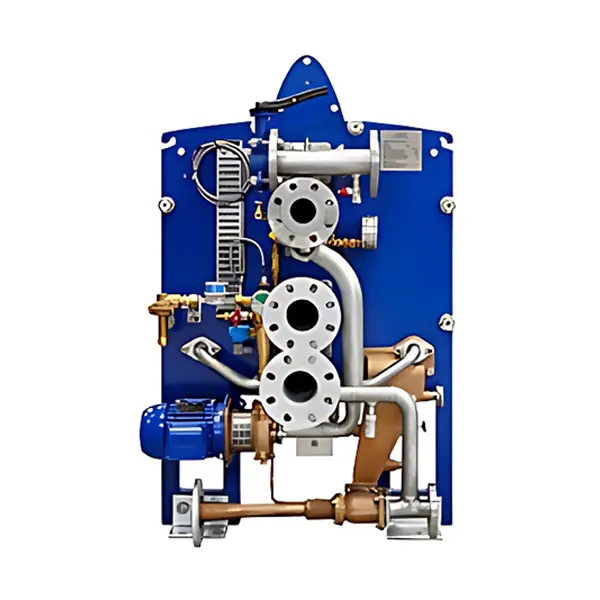

6. Easy Maintenance:

Some models of WPCHEs are designed to be easily disassembled for cleaning and maintenance, reducing downtime and maintenance costs.

7. Material Versatility:

WPCHEs can be made from a variety of materials, including stainless steel, titanium, and other alloys, to suit different chemical and temperature requirements.

Product Application

Food Industry

Shipbuilding Industry

Turbine Oil Cooling

Chemical Industry

District Heating

District Cooling

Swimming Pool Heating