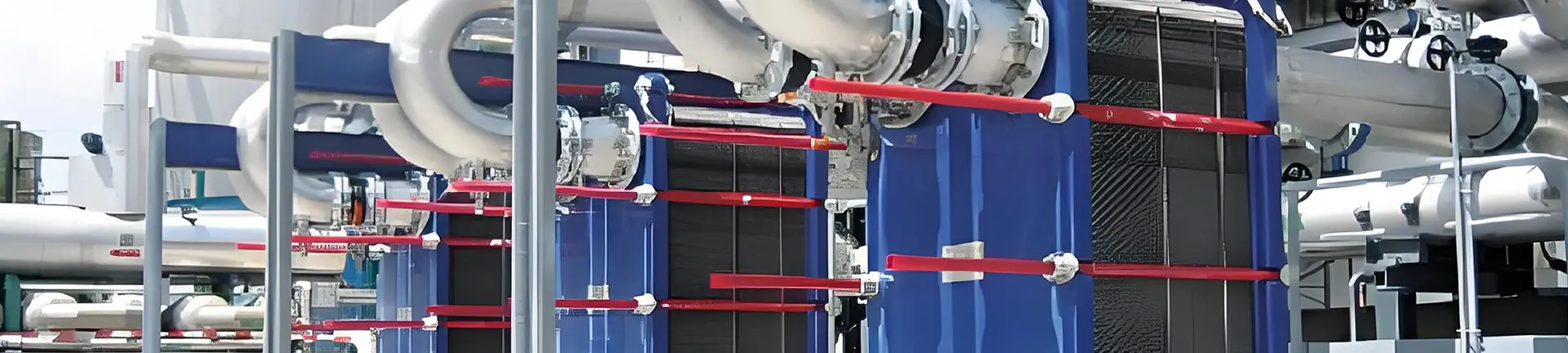

Welded Plate Heat Exchanger-WPHE

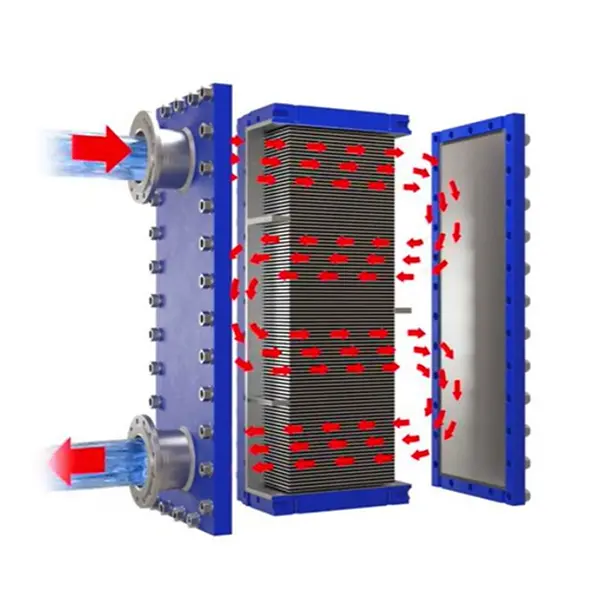

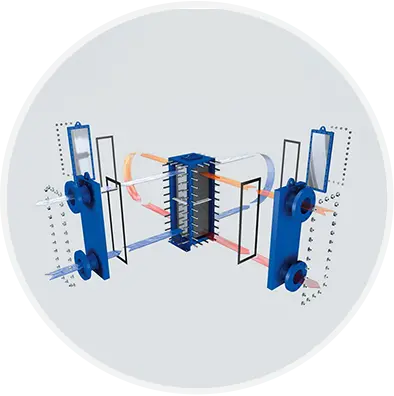

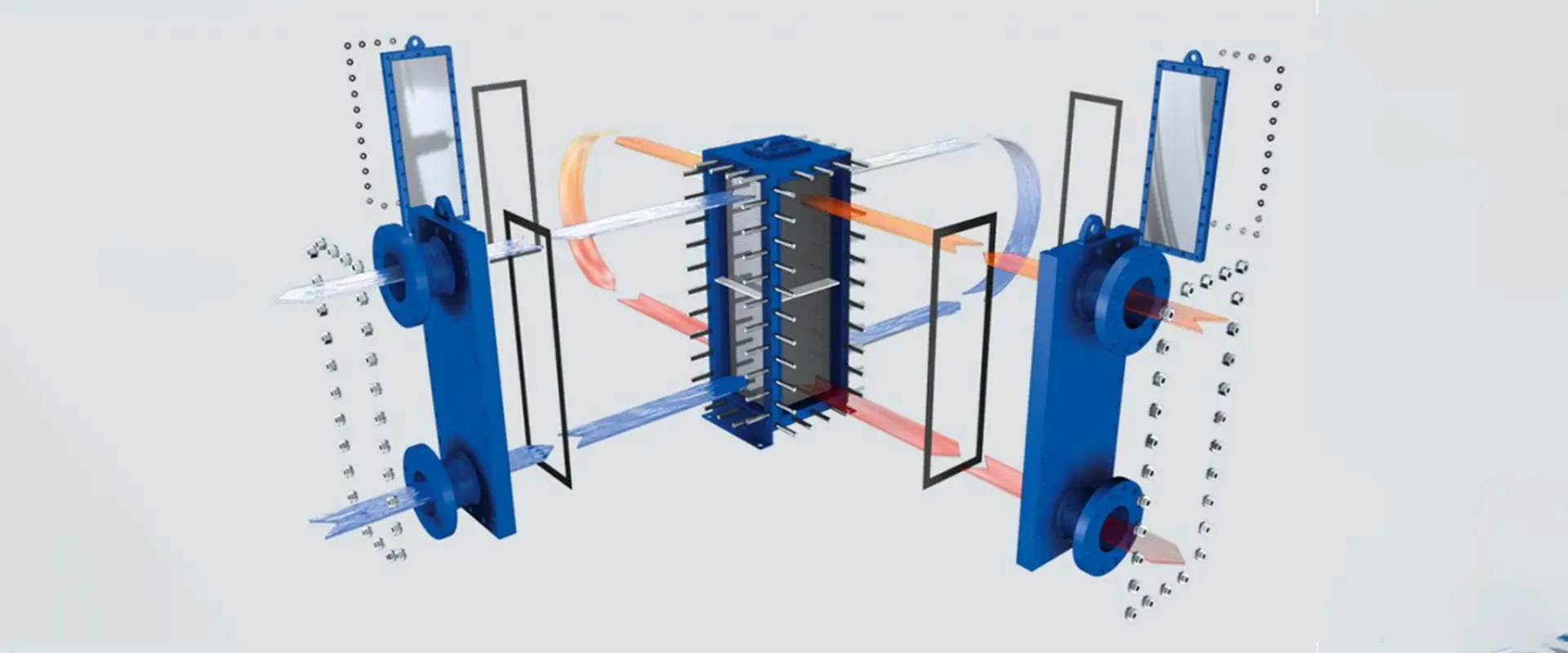

How does a welded plate heat exchanger work?

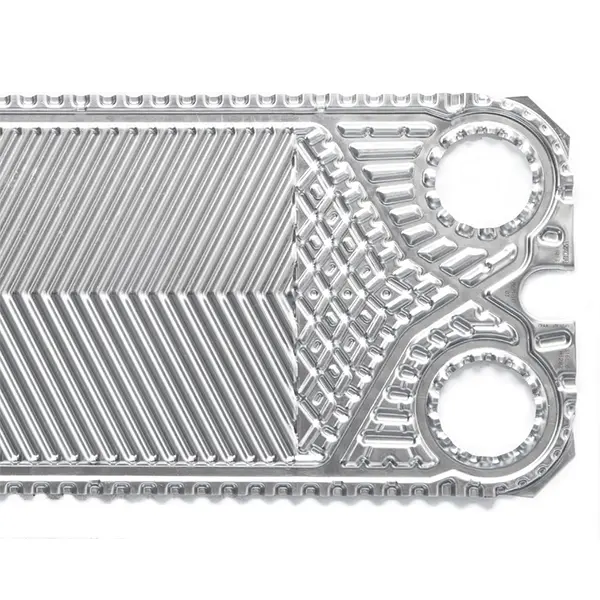

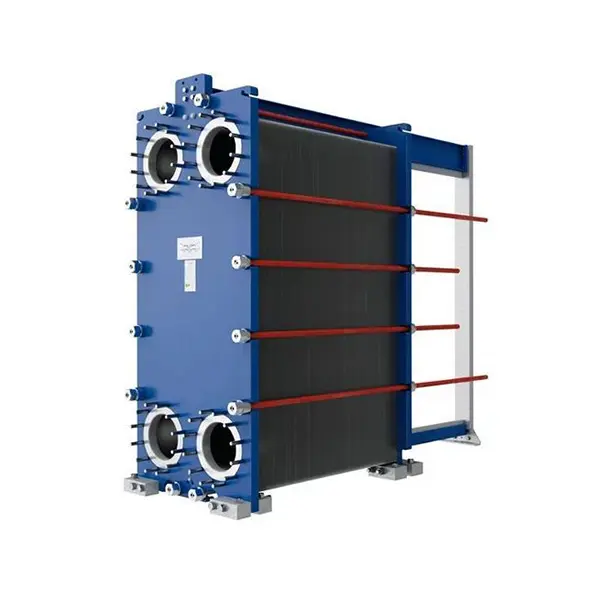

A WPHE consists of a series of thin metal plates welded together to form a series of channels or passages. The plates are designed to create a large surface area for heat transfer and are typically made of materials with high thermal conductivity, such as stainless steel or titanium. The two fluids that need to be heated or cooled flow through the different passages of the heat exchanger, with each fluid flowing through alternate passages. As the fluids flow past each other, heat is transferred between them through the thin metal plates.

Advantages of Welded Plate Heat Exchangers

1. Fully Welded without Gasket – Less prone to leakage, requiring less maintenance.

2. High Temperature/Pressure Resistance – Compared to shell and tube heat exchangers.

3. High Heat Exchange Efficiency – Less thermal resistance between fluids and plates.

4. Compact Structure – WPHEs are very compact and take up less space compared to other types of heat exchangers.

4. Reliable – High standards of quality and safety ensure all products meet rigorous requirements of GRG, FDA, and SGS certifications.

Basic Parameters of Welded Plate Heat Exchangers

-

Welded Plate Heat Exchanger

-

Materials: Stainless Steel (304L, 316L, 904L), Special Metals (254SMO, Hastelloy 276, Titanium, Nickel200/201, etc.)n

-

Plate Thickness: 0.8mm-1.2mm

-

Design Pressure: Max 40bar

-

Design Temperature: -196° to 400°

-

Technical Specifications and Design

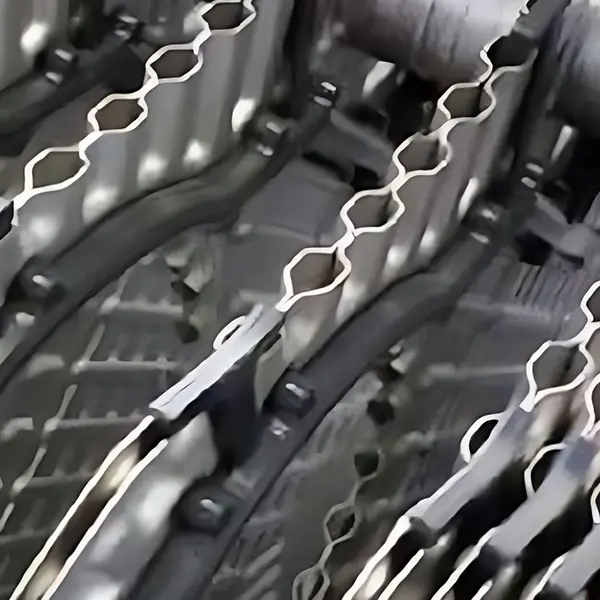

● Plate Corrugations: Different types of corrugations are available, such as chevron corrugation for high efficiency and pressure resistance, double dimple corrugation for highly viscous or solid-containing media, and the latest New Performance Chevron (NPC) for high-demand applications.

● Design Pressure and Temperature: WPHEs can operate at high pressures and temperatures, with some models designed to handle up to 42 bar and temperatures ranging from -50°C to 350°C.

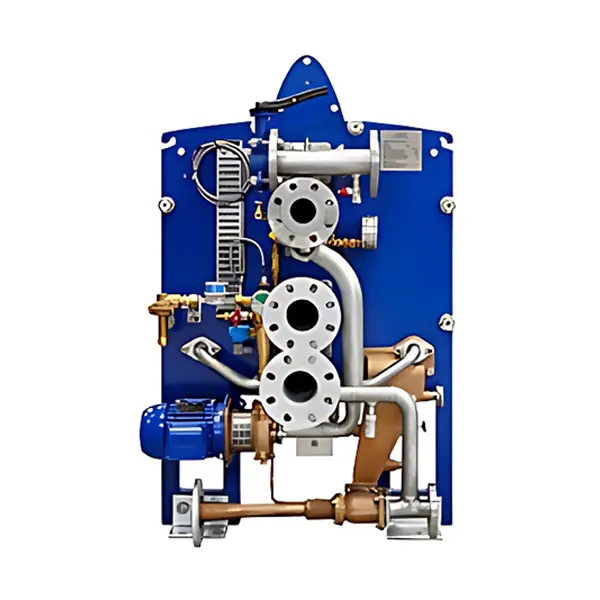

● Maintenance and Cleaning: WPHEs are designed for easy access for mechanical cleaning and visual inspections, reducing maintenance costs and downtime.

Application Field

Food Industry

Shipbuilding Industry

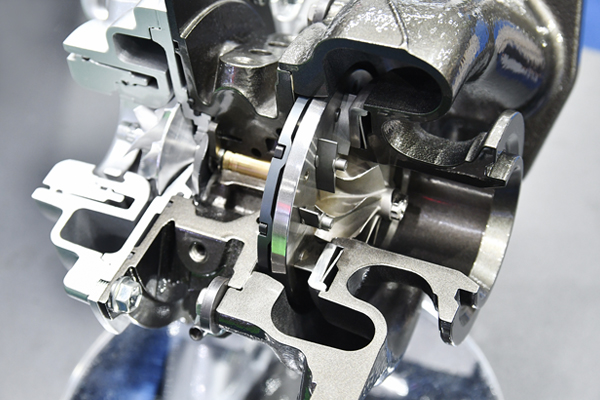

Turbine Oil Cooling

Chemical Industry

District Heating

District Cooling

Swimming Pool Heating